The performance of modern copiers depends on numerous intricate components working in perfect harmony, with the charge roller serving as one of the most critical elements in the electrophotographic printing process. This essential component plays a pivotal role in determining print quality, consistency, and overall machine reliability. Understanding how charge roller functionality impacts copier performance can help businesses make informed decisions about maintenance schedules and replacement strategies to ensure optimal output quality and operational efficiency.

Modern office environments demand consistent, high-quality document reproduction capabilities that can handle varying workloads while maintaining professional standards. The charge roller mechanism directly influences these performance metrics by controlling the initial electrostatic charging process that enables toner particles to adhere properly to paper surfaces. When this component functions optimally, users experience crisp text reproduction, accurate color rendering, and uniform density across all printed materials.

Understanding Charge Roller Functionality in Copier Systems

Primary Charging Process Mechanics

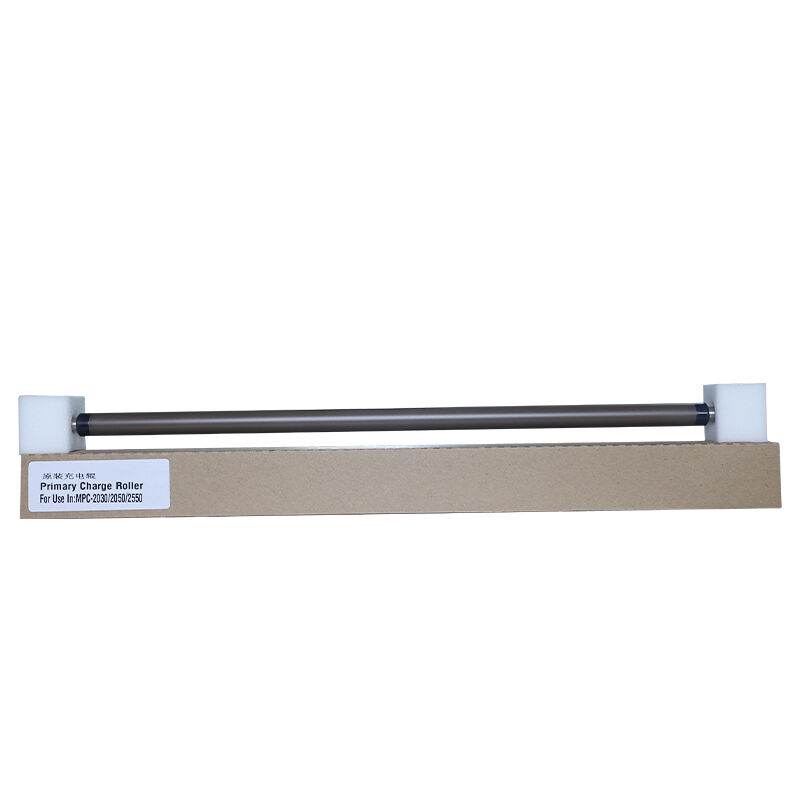

The charge roller operates as the primary charging device in laser printers and copiers, applying a uniform electrostatic charge across the photoconductor drum surface before image formation begins. This process creates the electrical foundation necessary for subsequent toner attraction and transfer operations. The roller maintains consistent contact pressure against the drum while rotating at synchronized speeds to ensure even charge distribution across the entire imaging surface.

During operation, the charge roller receives electrical current from the high-voltage power supply unit, typically ranging from negative 500 to 1000 volts depending on the specific copier model and manufacturer specifications. This electrical charge must remain stable throughout the printing cycle to prevent variations in print density or quality inconsistencies. The roller surface composition, usually consisting of conductive rubber or foam materials, facilitates uniform charge transfer while maintaining proper electrical isolation from other system components.

Integration with Photoconductor Systems

The relationship between the charge roller and photoconductor drum represents one of the most critical interfaces in the entire copier mechanism. These components must maintain precise mechanical alignment and electrical coordination to achieve consistent imaging results. The roller applies its charge uniformly across the drum surface, creating a blank slate for laser exposure or LED array illumination to selectively discharge specific areas corresponding to the desired image or text patterns.

Proper charge roller positioning ensures optimal contact pressure without excessive wear on either component surface. Manufacturers design these systems with specific tolerance requirements to maintain consistent performance throughout the component lifecycle. When alignment issues occur, users may notice streaking, banding, or density variations in their printed output, indicating the need for professional service attention or component replacement.

Impact on Print Quality and Consistency

Density Control and Uniformity

Print density consistency directly correlates with charge roller performance, as variations in the initial charging process create corresponding fluctuations in toner attraction and deposition. A properly functioning roller ensures that each point on the photoconductor receives identical electrical charge levels, resulting in uniform print density across the entire page surface. This consistency becomes particularly important for professional documents, marketing materials, and technical drawings where density variations can significantly impact visual quality and readability.

Environmental factors such as humidity, temperature, and dust accumulation can affect charge roller performance over time, leading to gradual density variations that may not be immediately apparent but compound into noticeable quality degradation. Regular monitoring of print samples can help identify these subtle changes before they become problematic, allowing for proactive maintenance interventions that preserve optimal performance standards.

Resolution and Detail Reproduction

Fine detail reproduction capabilities depend heavily on the charge roller's ability to maintain precise electrical characteristics across microscopic surface areas. When the roller provides consistent charging, the subsequent laser exposure or LED illumination can create sharp, well-defined discharged areas that correspond exactly to the intended image elements. This precision enables accurate reproduction of small text, fine lines, and detailed graphics that meet professional quality standards.

Charge roller degradation often manifests as reduced detail sharpness, with fine elements appearing fuzzy or poorly defined compared to fresh output quality. This deterioration typically occurs gradually, making it important for users to establish baseline quality references and monitor changes over time. Professional service technicians can assess charge roller condition through specialized testing procedures that measure electrical output consistency and surface condition.

Performance Degradation Patterns and Indicators

Early Warning Signs of Charge Roller Issues

Recognizing the early indicators of charge roller performance decline enables proactive maintenance strategies that prevent more serious system problems. Initial symptoms often include subtle variations in print density, particularly noticeable in large solid areas or graduated tones where even small charging inconsistencies become visible. Users may observe slight streaking patterns, especially in areas with heavy toner coverage, or notice that fine text appears less sharp than previous output.

Color accuracy can also serve as an early indicator of charge roller problems, as inconsistent charging affects toner deposition patterns that directly impact color reproduction quality. Business users who regularly produce marketing materials or client presentations should pay particular attention to color consistency across multiple copies of the same document, as variations may indicate developing charge roller issues requiring professional attention.

Progressive Performance Deterioration

As charge roller condition continues to decline, performance issues become more pronounced and widespread throughout printed output. Advanced degradation typically manifests as prominent streaking, banding patterns, or significant density variations that affect document readability and professional appearance. These symptoms indicate that the roller surface has accumulated sufficient contamination or wear to prevent uniform charge distribution across the photoconductor drum.

Mechanical wear patterns on the charge roller surface can create recurring defects that appear consistently in the same relative positions on sequential pages. This cyclical pattern occurrence helps service technicians identify charge roller problems versus other potential causes of print quality issues. Understanding these diagnostic patterns enables more efficient troubleshooting and targeted component replacement strategies.

Maintenance Strategies for Optimal Performance

Preventive Care Approaches

Implementing comprehensive preventive maintenance protocols significantly extends charge roller lifespan while maintaining consistent copier performance throughout the component service interval. Regular cleaning procedures remove accumulated toner particles, paper dust, and environmental contaminants that can interfere with proper electrical charge distribution. Professional service schedules should include specific charge roller inspection and cleaning procedures using appropriate materials and techniques.

Environmental controls within the copier installation area contribute substantially to charge roller longevity and performance consistency. Maintaining stable temperature and humidity levels reduces stress on roller materials while minimizing contamination accumulation. Proper ventilation systems help remove airborne particles that can settle on internal components, while dust filtration reduces the introduction of abrasive materials that accelerate wear patterns.

Replacement Timing and Procedures

Determining optimal charge roller replacement timing requires balancing performance quality requirements against component costs and service scheduling considerations. Most manufacturers provide recommended replacement intervals based on page volume or time periods, but actual replacement needs may vary depending on usage patterns, environmental conditions, and quality standards. Professional assessment of current performance levels helps establish appropriate replacement schedules tailored to specific operational requirements.

Proper replacement procedures ensure that new charge roller components integrate seamlessly with existing copier systems while delivering expected performance improvements. Professional installation includes calibration procedures that optimize electrical characteristics and mechanical alignment for maximum performance and longevity. These calibration steps often involve adjustments to charging voltages and timing parameters that require specialized knowledge and testing equipment.

FAQ

How often should charge rollers be replaced in typical office copiers?

Charge roller replacement intervals typically range from 50,000 to 150,000 pages depending on the specific copier model, usage patterns, and environmental conditions. High-volume business environments may require more frequent replacement due to accelerated wear, while light-duty applications can often achieve longer service intervals. Regular performance monitoring and professional assessment help determine optimal replacement timing for individual installations.

What are the most common causes of premature charge roller failure?

Environmental contamination, excessive humidity, temperature fluctuations, and improper maintenance procedures represent the primary causes of premature charge roller failure. Dust accumulation, toner particle buildup, and mechanical damage from foreign objects can significantly reduce component lifespan. Implementing proper environmental controls and following manufacturer maintenance guidelines helps minimize these risk factors.

Can charge roller problems affect other copier components?

Yes, defective charge rollers can cause secondary damage to photoconductor drums, developer units, and transfer mechanisms through improper electrical charging or mechanical interference. Poor charge distribution creates uneven toner deposition patterns that stress downstream components and can accelerate overall system wear. Prompt attention to charge roller issues prevents cascading component failures and reduces total repair costs.

How can users identify charge roller issues before they become severe?

Regular print quality monitoring using test patterns and sample documents helps identify subtle charge roller degradation before it affects normal business operations. Users should watch for gradual changes in density consistency, color accuracy, and fine detail reproduction quality. Establishing baseline quality references and conducting periodic comparisons enables early detection of developing problems that benefit from proactive maintenance intervention.