The Fundamental Role of the Drum Unit

What is a Printer Drum Unit?

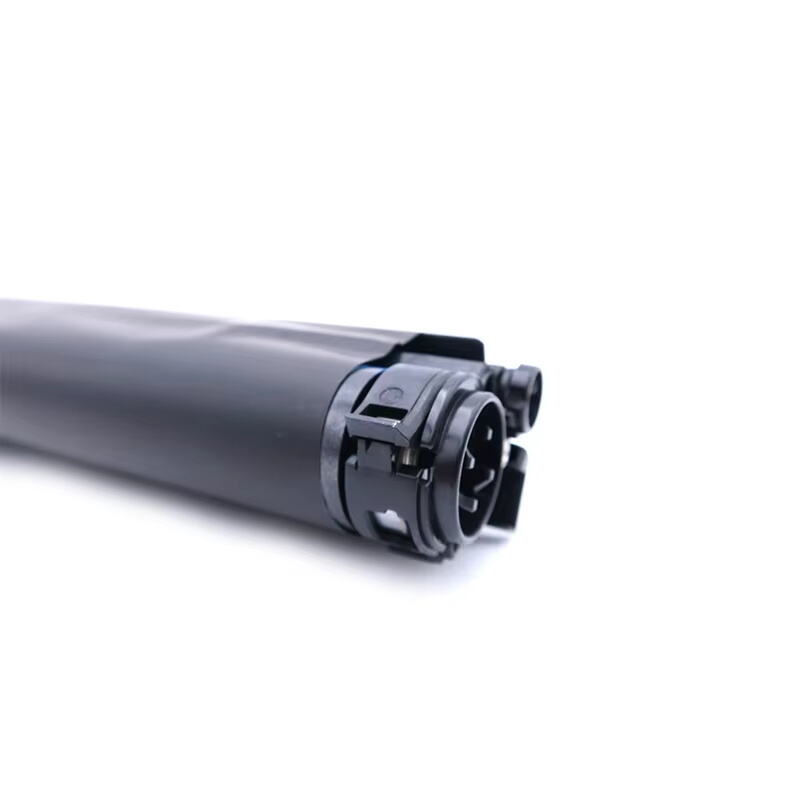

The drum unit plays a major role in laser printers by getting toner onto paper where it belongs. Think of it almost like a bridge between what's on screen and what ends up printed out physically. Most drum units have this cylinder shape covered in special light-sensitive stuff. That coating matters because without it, the drum wouldn't be able to work with those electric charges needed for actual printing to happen. Pretty much every time someone hits print, these components are doing their thing behind the scenes to make sure everything comes out right.

Drum units come in different forms for printers, mainly integrated and separate models designed for particular machines. The integrated type puts the photosensitive drum right inside the toner cartridge, making it super easy when it's time to replace. Separates work differently though they require swapping out just the drum part separately from the toner. While this might seem like extra work, many users find that separate drums actually save money over time since they don't have to replace both components at once.

The lifespan of a drum unit can vary significantly depending on usage and manufacturer specifications, typically ranging from thousands to tens of thousands of pages. Understanding these differences is pivotal for selecting the right component for your printing needs.

Core Function in the Electrostatic Printing Process

Electrostatic printing plays a key role in how images get created, and the drum unit is pretty much essential for making it all work. At first, the surface of the drum gets charged evenly across the board, which basically prepares everything for when the toner comes into play later on. When actually printing happens, there's a laser that goes to work on certain parts of the drum surface. This creates what amounts to an electrostatic map matching exactly what needs to appear as either text or pictures eventually.

After the laser etches out the desired pattern, we apply toner that carries an opposite charge. This toner sticks to the parts of the drum that were neutralized by the laser action. When the paper comes into contact with this charged drum, it pulls the toner onto itself to form the actual image. The drum plays a pretty big role in how good the final print looks. If the drum isn't working properly, it can really mess with the definition of text and images. That's why manufacturers spend so much time testing these components before they ship printers to customers.

Research indicates there's a clear link between how well drum units are maintained and the consistency of print quality they produce. When kept in good condition, these components keep working smoothly and deliver sharp images job after job. Regular cleaning and inspection does more than just improve what comes out of the printer though. It actually extends how long the drum lasts before needing replacement, which makes sense for anyone wanting their printing operations to run without constant interruptions or expensive part swaps down the road.

How Drum Unit Performance Directly Affects Print Quality

Toner Transfer Precision and Image Formation

Getting the toner transfer right makes all the difference when it comes to good quality prints. When something goes off track during this process, the results tend to look pretty bad. The drum unit plays a big role here too. If everything works properly, the toner gets applied just right on the paper surface, which means we end up with those nice clean images everyone wants. But what happens if the drum isn't performing well? Well, problems start showing up fast. We might see prints that are too light, have strange streaks running through them, or worse yet, get smudged completely. Industry pros know that even small flaws in how these drum units operate can mess up image formation badly enough that lines become fuzzy and text looks unclear. Most professionals stress regular checkups and maintenance routines to keep things running smoothly. After all, there's no getting around the fact that accurate toner placement leads straight to better looking printed materials.

Common Quality Issues from Drum Degradation

As drum units start to wear down, most people will see some pretty obvious printing problems showing up on their pages. Think about things like those annoying bands across the page, strange ghost images appearing where they shouldn't be, or just generally inconsistent print quality overall. The drum gets damaged through normal use over time, but also from all sorts of environmental stuff we don't always think about - too much moisture in the air, super hot or cold environments, even mishandling during installation or replacement. All these factors mess with the delicate surface of the drum, making it harder for toner to stick properly to paper. According to various industry stats out there, quite a few folks actually struggle with bad print quality because their drum unit is acting up. That's why regular checkups matter so much. Following what the manufacturer recommends and sticking with genuine parts really helps prevent this kind of breakdown and keeps prints looking good day after day.

Symptoms of Drum Unit Failure and Performance Decline

Visible Print Defects and Error Indicators

Knowing when a drum unit starts acting up matters a lot if we want our printers running smoothly. When things go wrong, people tend to notice stuff like prints that look washed out, weird streaks across pages, or smudgy areas where ink just doesn't stick right. The drum plays a big role in getting toner onto paper properly, so even small scratches or inconsistencies on its surface will mess up the final product. Most folks have seen those long black lines running down printed documents at some point these typically mean the drum surface has worn down over time. Little dark spots scattered around? That's usually leftover toner particles or dirt buildup somewhere inside the machine. Many modern printers actually come with built-in warnings that light up or beep when something's not quite right with the drum component. Manufacturers definitely list all these issues as red flags for drum problems in their manuals. Fixing them early saves money in the long run and keeps documents looking professional instead of embarrassing.

Diagnosing Drum-Related Printer Malfunctions

When something goes wrong with printer drums, there are several straightforward steps that usually fix problems before they get expensive. First thing to do is check printed pages carefully looking for telltale signs like faded areas (ghosting) or dark stripes running across the page (banding). Most modern printers come with built-in diagnostics that flash error codes when something's off track. Don't forget to actually look at the drum itself too - sometimes dirt buildup or small cracks show up under close inspection. Tech support folks always stress keeping those manufacturer service manuals handy during troubleshooting sessions. Following this basic approach typically gets most drum issues sorted out pretty quickly, which means fewer paper jams and better looking documents overall.

Maintenance Practices to Optimize Drum Unit Longevity

Proper Handling and Environmental Considerations

Handling drum units requires attention to detail, particularly when installing or replacing them to avoid any accidental damage. Always treat these parts gently since they have sensitive surfaces that can easily get scratched or worn down. Want your drum unit to last longer? Keep it in good environmental conditions. Humidity is a big factor here. Most drum units work well when the air isn't too dry or too moist, ideally around 40% to 60% humidity. Temperature matters too, with 20 degrees Celsius to 25 degrees being the sweet spot for most models. Industry data suggests that sticking to these ranges can actually make a drum unit last about 20% longer than usual. Following these simple storage and handling tips makes sense both economically and practically, ensuring better print quality over time and saving money on replacements down the road.

Cleaning Procedures and Usage Guidelines

Keeping drum units clean regularly makes all the difference for good performance. The basic cleaning involves gently wiping away toner buildup and any dirt that gets stuck on the drum surface. This helps avoid those annoying print issues we've all seen before - streaks running across pages or random spots appearing where they shouldn't be. Most manufacturers have some sort of usage rules too. These usually cover things like how often the printer gets used throughout the day and what kind of print density settings work best with different drum models. A lot of folks in the know recommend giving the drum a thorough cleaning about every half year or right after changing out the toner cartridge. And don't forget about handling the drum properly when installing or removing it from the printer. Using too much force will just wear it down faster than normal. People who take the time to learn these maintenance tips generally find their printers produce better quality prints for longer periods without needing replacement parts.

Drum Unit Replacement Strategies

Lifespan Expectations and Replacement Timing

Knowing how long drum units last and when they need replacing helps keep printed materials looking good. The page count varies quite a bit between different drum models, so this affects replacement schedules pretty significantly. Some models might handle about 12 thousand pages before issues start showing up, whereas higher quality ones can sometimes go all the way to 30 thousand pages or more without major problems. When should someone think about getting a new drum? Look out for telltale signs like prints that look washed out, strange streak patterns appearing across pages, or random spots showing up where there shouldn't be any. Most people notice these things happening right around when their drum reaches the end of its useful life. According to industry data, changing drums at the right time actually improves printing results by roughly 15 percent. That means documents come out clearer and look much more professional overall.

OEM vs. Compatible Units: Key Selection Factors

When choosing between Original Equipment Manufacturer (OEM) drum units and third party alternatives, there are quite a few things worth considering. The manufacturers design OEM units specifically for their copiers, which means they fit just right and usually come with some kind of performance guarantee. Most people find them pretty reliable, though let's face it, they do cost a lot more money upfront. Third party drum units give companies a cheaper option without sacrificing too much in terms of performance sometimes even better than OEM stuff according to some reports. But there are drawbacks too warranty problems pop up occasionally, and the print quality might not be as consistent across different batches. According to recent research published in a major printing publication, around two thirds of businesses stick with OEM drums because they know exactly what they're getting when it comes to quality and how well everything works together. Still, almost half go for the cheaper route despite possible headaches down the line. Before making any decisions about replacing drum units, companies should really think through their actual printing demands and financial constraints first.

To explore options for compatible drum units, consider checking with reputable third-party manufacturers who provide satisfactory warranties and quality assurances.

Frequently Asked Questions

What are the signs that indicate a drum unit needs replacement?

Signs that a drum unit needs replacement include faded print, streaks, spots on documents, and error indicators on printers suggesting drum issues.

How does proper maintenance affect the lifespan of a drum unit?

Proper maintenance can significantly prolong a drum unit's lifespan by ensuring the drum surface remains free of toner residue and debris, preventing print defects.

What environmental conditions are best for optimal drum unit performance?

Optimal environmental conditions for drum units are humidity levels between 40% and 60% and temperatures ranging from 20°C to 25°C.

What is the difference between OEM and compatible drum units?

OEM drum units are made by the printer's manufacturer for assured compatibility, while compatible units are cost-effective alternatives with potential variability in performance.