Understanding the Critical Role of Upper Fuser Rollers in Print Technology

In the intricate world of printing technology, the upper fuser roller stands as a crucial component that directly impacts print quality and document durability. This essential element works in conjunction with other printer parts to ensure that toner particles are properly melted and permanently bonded to paper. Located in the heart of a printer's fusing assembly, the upper fuser roller applies both heat and pressure to create the final printed output we rely on daily.

Modern printing systems, whether in office environments or industrial settings, depend heavily on the proper functioning of the upper fuser roller to maintain consistent print quality. This component's performance affects everything from text clarity to image definition, making it a cornerstone of reliable printing operations.

Core Components and Construction of Upper Fuser Rollers

Material Composition and Design Features

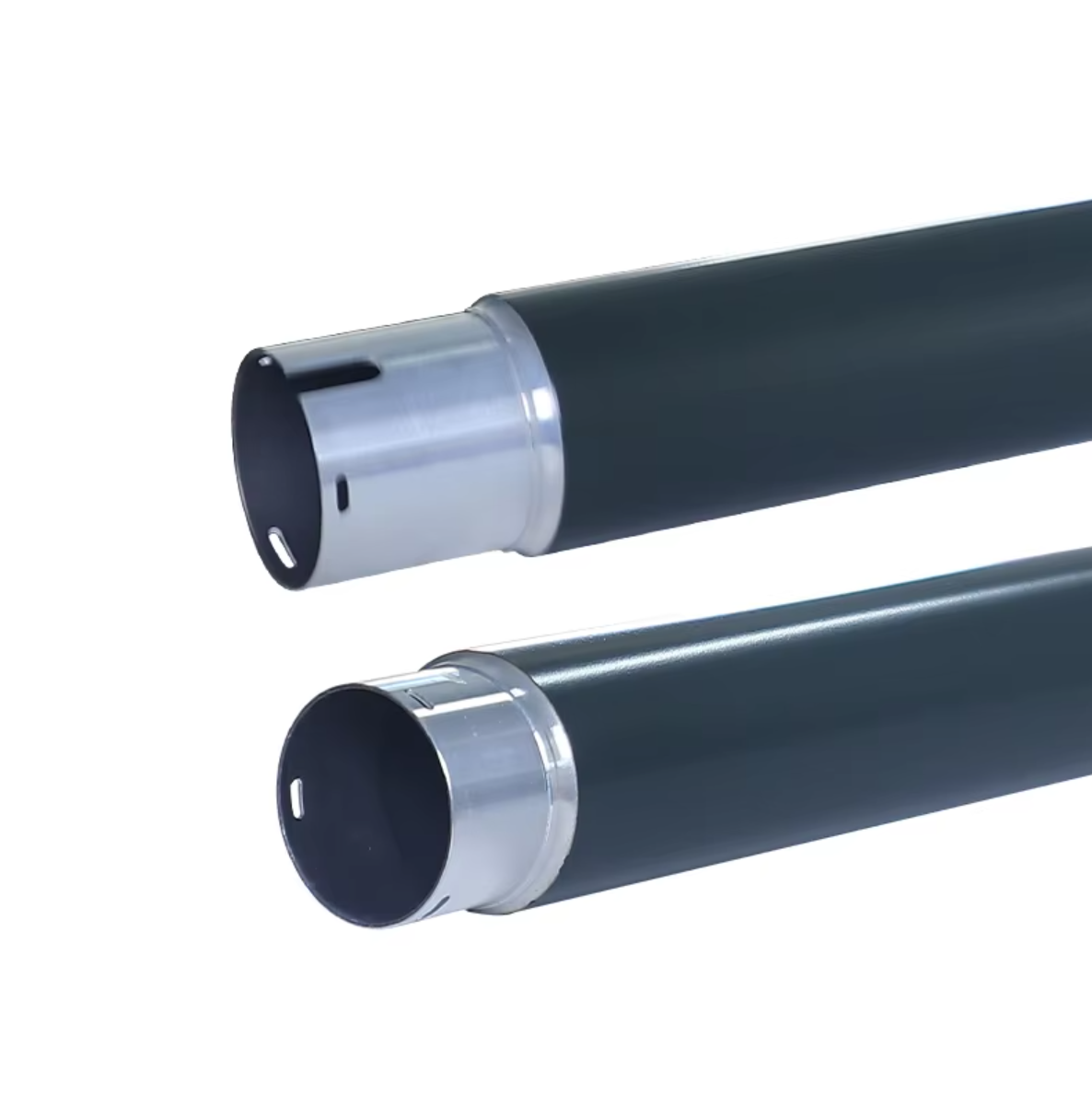

The upper fuser roller typically consists of an aluminum core cylinder coated with specific materials designed for optimal heat distribution. This metallic core ensures even heat distribution across the entire printing surface. The outer layer usually features a non-stick coating, often made from Teflon or similar materials, which prevents toner from adhering to the roller surface while maintaining consistent heat transfer properties.

Advanced upper fuser roller designs incorporate multiple layers, each serving a specific purpose. The base layer provides structural integrity, while intermediate layers manage heat distribution. The outermost layer ensures smooth paper transport and proper toner fusion. This sophisticated construction helps maintain precise temperature control throughout the printing process.

Temperature Control Mechanisms

Temperature regulation in an upper fuser roller involves sophisticated heating elements and sensors. These components work together to maintain the optimal temperature range required for proper toner fusion. Internal thermistors constantly monitor temperature variations, while control circuits make rapid adjustments to ensure consistent heat output.

Most modern upper fuser roller assemblies operate at temperatures between 160-220 degrees Celsius, depending on the specific printer model and paper type being used. This precise temperature control is crucial for preventing common printing issues such as toner flaking or incomplete fusion.

Operational Principles and Functionality

Heat and Pressure Application Process

The primary function of an upper fuser roller involves applying controlled heat and pressure to the printed page. As paper passes through the fuser assembly, the upper fuser roller works in tandem with the lower pressure roller to create a precise nip point. This combination of heat and pressure ensures that toner particles melt and permanently bond with the paper fibers.

During operation, the upper fuser roller maintains constant contact with the paper while rotating at a carefully calibrated speed. This movement helps prevent paper jams while ensuring uniform toner fusion across the entire page. The process must be precisely timed to prevent paper damage while achieving optimal print quality.

Toner Fusion Mechanics

The science behind toner fusion relies heavily on the upper fuser roller's ability to quickly heat toner particles to their melting point. When toner reaches the appropriate temperature, it transitions from a powder state to a semi-liquid form that can effectively bond with paper fibers. The pressure applied during this process ensures complete and even adhesion.

Modern upper fuser roller systems are designed to handle various toner formulations and paper types. The roller's surface properties and temperature controls must adapt to these different materials while maintaining consistent print quality and preventing common issues like ghosting or incomplete fusion.

Maintenance and Performance Optimization

Regular Maintenance Requirements

Proper maintenance of the upper fuser roller is essential for optimal printer performance. Regular cleaning helps prevent toner buildup and ensures consistent heat transfer. Maintenance schedules typically include periodic inspection of the roller surface for wear or damage, cleaning of any residual toner, and verification of proper temperature control functionality.

Professional technicians recommend checking the upper fuser roller's condition after specific print volume thresholds or when print quality issues arise. This proactive approach helps prevent more serious problems and extends the component's operational lifespan.

Troubleshooting Common Issues

When problems occur with the upper fuser roller, they often manifest as specific print quality issues. Common indicators include wrinkled pages, toner smearing, or uneven print density. Understanding these symptoms helps technicians quickly identify and resolve problems before they lead to more serious equipment damage.

Regular monitoring of print quality and mechanical operation can help detect early signs of upper fuser roller wear or malfunction. This awareness enables timely maintenance or replacement, preventing costly downtime and ensuring consistent print quality.

Technological Advancements and Future Developments

Innovation in Fuser Technology

Recent advances in upper fuser roller technology have focused on improving energy efficiency and reducing warm-up times. New materials and coating technologies offer better heat distribution while requiring less energy input. These improvements contribute to both environmental sustainability and operational cost reduction.

Manufacturers continue to develop more durable surface coatings and advanced temperature control systems for upper fuser rollers. These innovations aim to extend component lifespan while maintaining consistent print quality across a wider range of media types.

Environmental Impact and Sustainability

Modern upper fuser roller designs increasingly incorporate eco-friendly materials and manufacturing processes. Reduced energy consumption during operation and improved durability help minimize environmental impact while maintaining high performance standards. These developments align with growing industry focus on sustainability and environmental responsibility.

Future developments in upper fuser roller technology are expected to further reduce energy requirements while improving print quality and speed. These advances will likely incorporate smart monitoring systems and self-adjusting features to optimize performance automatically.

Frequently Asked Questions

How long does an upper fuser roller typically last?

An upper fuser roller's lifespan varies depending on usage patterns and maintenance practices, but typically ranges from 100,000 to 300,000 pages. Regular maintenance and proper operating conditions can significantly extend this lifespan.

Can an upper fuser roller be cleaned or repaired?

While professional cleaning is possible and recommended as part of regular maintenance, repair options for damaged upper fuser rollers are limited. In most cases, a worn or damaged roller will need to be replaced to maintain optimal print quality.

What causes upper fuser roller failure?

Common causes of upper fuser roller failure include normal wear and tear, paper jams, improper maintenance, and temperature control issues. Using inappropriate paper types or operating the printer outside its specified environmental conditions can also contribute to premature failure.