Understanding Transfer Belt Maintenance and Longevity

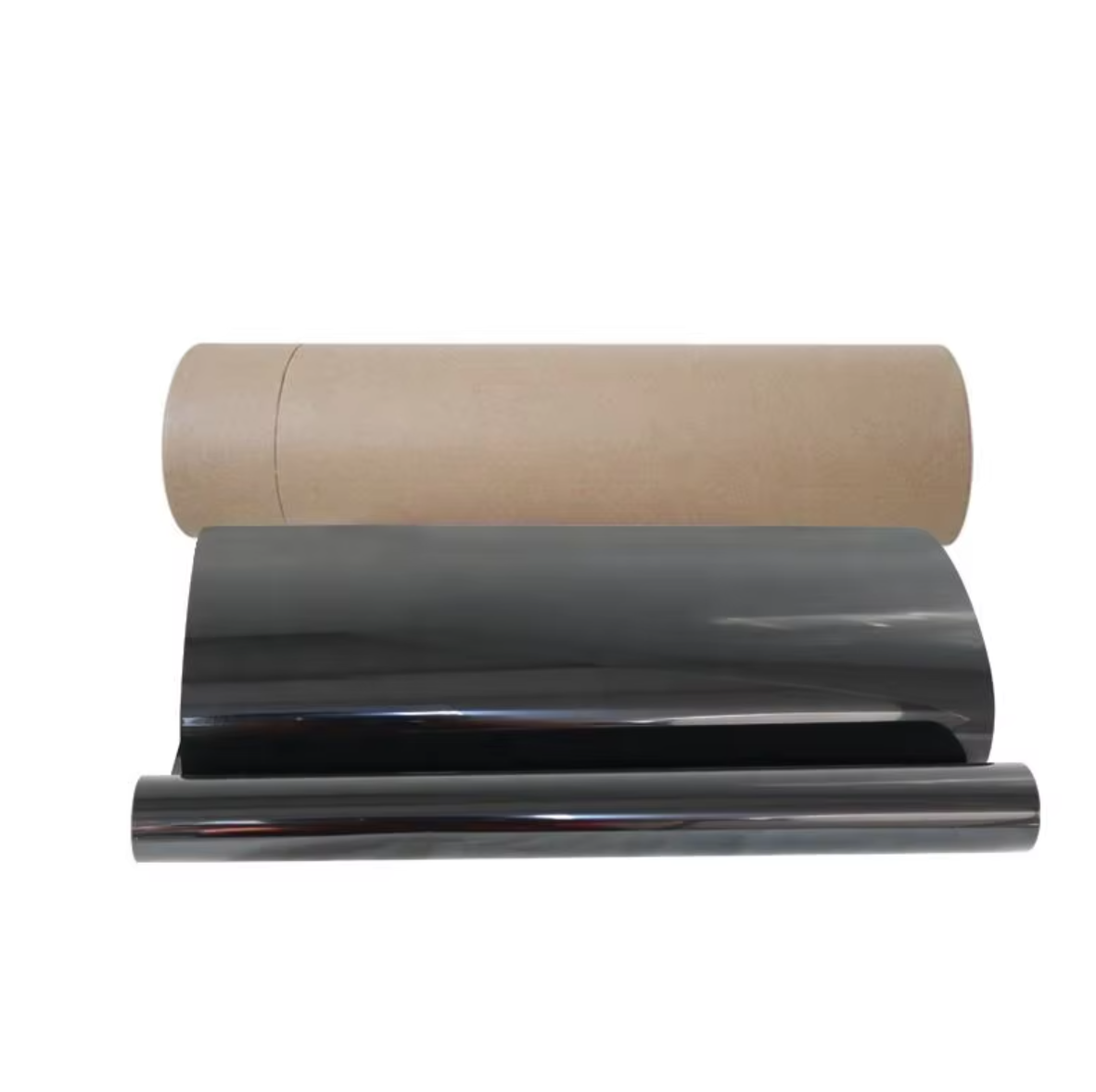

Transfer belts are critical components in various mechanical systems, serving as essential elements for power transmission and material handling. Whether in industrial machinery, printing equipment, or conveyor systems, these belts play a vital role in ensuring smooth operations. Recognizing when a transfer belt requires replacement is crucial for maintaining system efficiency and preventing costly breakdowns.

The lifespan of a transfer belt depends on multiple factors, including usage intensity, environmental conditions, and maintenance practices. Regular inspection and timely replacement not only optimize performance but also protect connected components from potential damage. Let's explore the comprehensive aspects of transfer belt assessment and maintenance.

Visual Inspection Methods for Transfer Belts

Surface Wear Indicators

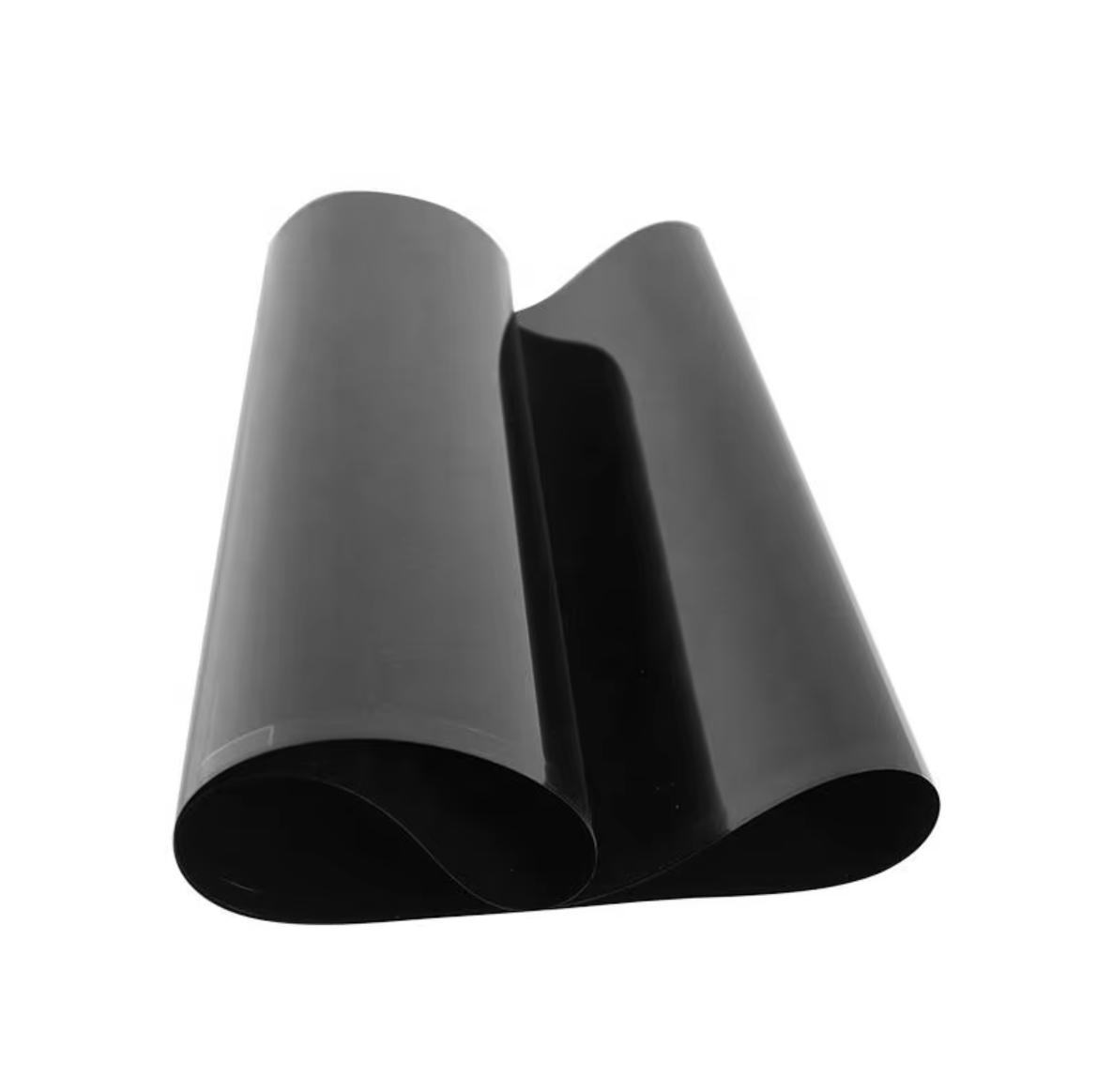

One of the most immediate ways to assess a transfer belt's condition is through visual inspection of its surface. Look for signs of excessive wear, such as cracks, fraying edges, or missing chunks of material. The belt's surface should maintain consistent texture and thickness throughout its length. Any noticeable variations could indicate underlying problems.

Advanced wear patterns might include glazing on the belt's surface, which appears as a shiny, hardened area. This condition often results from excessive heat buildup and can significantly reduce the belt's grip and efficiency. If you observe these signs, it's time to consider a replacement.

Structural Integrity Assessment

Beyond surface examination, evaluating the transfer belt's structural integrity is crucial. Check for signs of separation between the belt's layers, which might appear as bubbling or delamination. These issues often begin small but can quickly escalate into major problems that compromise the belt's functionality.

Pay special attention to the belt's edges, as they often show the first signs of deterioration. Frayed or uneven edges can indicate misalignment issues or excessive wear that requires immediate attention. Regular monitoring of these aspects helps prevent unexpected failures.

Performance-Based Evaluation Techniques

Operational Efficiency Monitoring

The transfer belt's performance during operation provides valuable insights into its condition. Listen for unusual noises such as squealing or grinding sounds, which often indicate improper tension or alignment issues. Pay attention to how smoothly the system operates – any jerky movements or inconsistent power transmission might signal a deteriorating belt.

Track the system's energy consumption patterns, as a failing transfer belt often requires more power to maintain the same level of performance. This increased energy demand results from reduced efficiency and can serve as an early warning sign of impending failure.

Load Handling Capabilities

Observe how the transfer belt handles its designated load. A belt in good condition maintains consistent speed and tension under normal operating conditions. If you notice slippage, especially under standard loads, this could indicate wear beyond acceptable limits.

Regular load testing, within safe parameters, can help identify gradual deterioration before it leads to failure. Document these tests and compare results over time to establish trends in performance degradation.

Environmental Impact Assessment

Temperature and Humidity Effects

Environmental conditions significantly influence transfer belt longevity. High temperatures can accelerate wear and cause material degradation, while excessive humidity might promote premature aging or material breakdown. Monitor the operating environment and look for signs of environmental stress on the belt.

Consider implementing temperature monitoring systems in critical applications. Regular readings above recommended thresholds might necessitate more frequent inspections or indicate the need for enhanced cooling measures to protect the transfer belt.

Chemical Exposure Evaluation

Chemical exposure can dramatically affect a transfer belt's lifespan. Regular inspection for signs of chemical damage, such as material softening, hardening, or color changes, is essential. Document any exposure to oils, solvents, or other chemicals that might compromise the belt's integrity.

Maintain detailed records of environmental conditions and any chemical incidents. This information helps in predicting potential issues and planning preventive maintenance schedules effectively.

Maintenance History Analysis

Service Interval Tracking

A comprehensive maintenance history provides valuable context for replacement decisions. Track installation dates, service intervals, and previous repairs to establish patterns and predict optimal replacement timing. Regular maintenance records help identify recurring issues that might indicate underlying problems.

Compare actual service life against manufacturer recommendations. Significant deviations might suggest problems with installation, application, or operating conditions that need addressing before installing a new transfer belt.

Performance Trend Analysis

Analyze historical performance data to identify gradual degradation patterns. This analysis should include efficiency measurements, power consumption trends, and maintenance frequency. Understanding these patterns helps optimize replacement timing and minimize operational disruptions.

Document any modifications to operating conditions or load requirements, as these changes can affect the transfer belt's wear rate and expected lifespan. Use this information to refine maintenance schedules and replacement criteria.

Frequently Asked Questions

How often should transfer belts be inspected?

Transfer belts should undergo visual inspection at least monthly, with more frequent checks in high-stress applications or harsh environments. Detailed performance evaluations should be conducted quarterly, while comprehensive assessments including load testing might be performed semi-annually or annually, depending on usage intensity and manufacturer recommendations.

What are the most common signs of transfer belt failure?

Key indicators include visible cracks or fraying, unusual noises during operation, inconsistent power transmission, increased energy consumption, and frequent slippage under normal loads. Surface glazing, edge damage, and separation between layers are also significant warning signs that warrant immediate attention.

Can environmental conditions affect transfer belt lifespan?

Yes, environmental factors significantly impact transfer belt durability. High temperatures, excessive humidity, exposure to chemicals or UV radiation, and extreme temperature fluctuations can accelerate wear and degradation. Proper environmental control and protection measures can help extend belt life and maintain optimal performance.