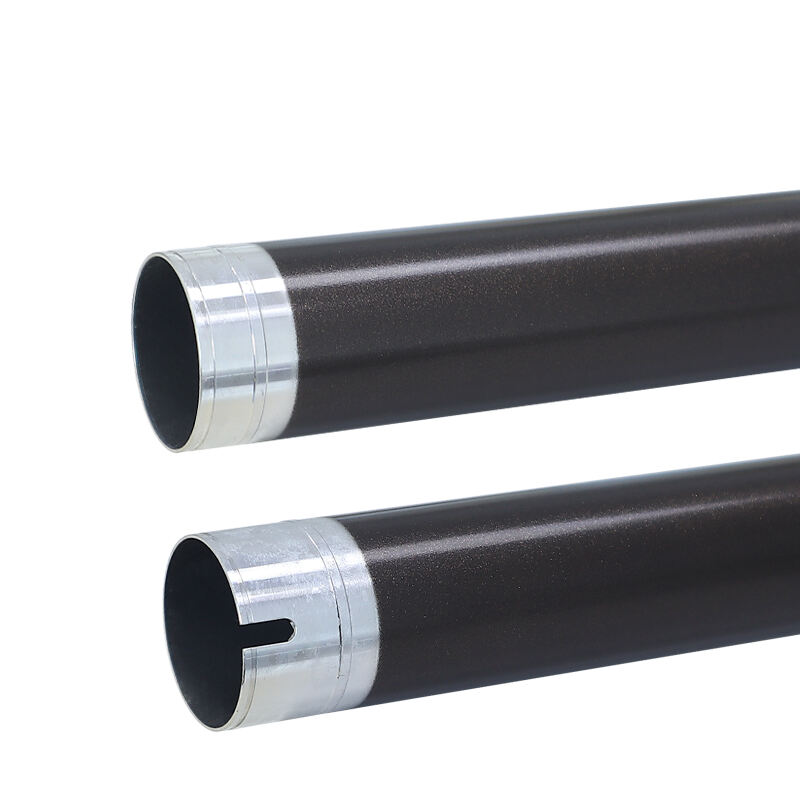

upper fuser roller quotation

The upper fuser roller quotation represents a comprehensive assessment of high-quality components essential for printer maintenance and optimization. This crucial element plays a vital role in the printing process by applying controlled heat and pressure to permanently bond toner to paper. The quotation encompasses detailed specifications for rollers manufactured with advanced silicone rubber coating technology, ensuring optimal heat distribution and consistent printing quality. These rollers are designed with precision-engineered cores that maintain dimensional stability under high-temperature conditions, typically operating between 160-220 degrees Celsius. The quotation includes various size options to accommodate different printer models and production requirements, with diameters ranging from 20mm to 50mm and lengths customizable according to specific printer specifications. The pricing structure reflects considerations for bulk ordering, material quality grades, and specialized coating options that can enhance durability and performance. Each quoted roller undergoes rigorous quality control measures, including thermal conductivity testing, hardness measurements, and surface finish evaluations to ensure compliance with industry standards.