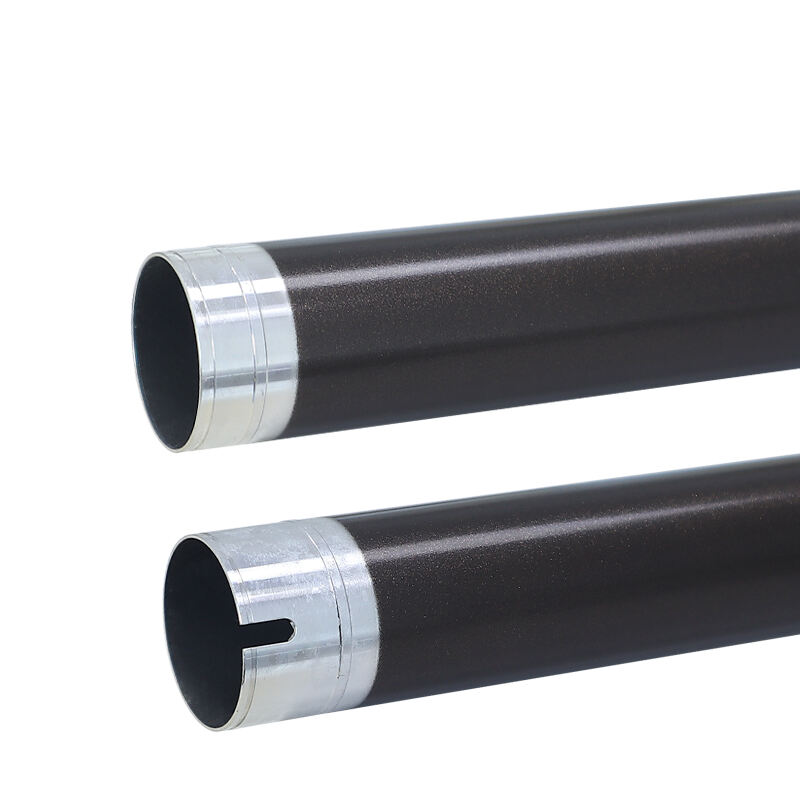

upper fuser roller

The upper fuser roller is a critical component in printing and copying systems, designed to effectively apply heat and pressure during the printing process. This essential element works in conjunction with the lower pressure roller to create the perfect fusion of toner particles onto paper. Operating at temperatures typically ranging from 160-200 degrees Celsius, the upper fuser roller features a specialized coating that prevents toner adhesion while ensuring optimal heat distribution. Its construction usually consists of an aluminum core covered with silicone rubber or fluororesin layers, providing both durability and consistent performance. The roller's surface maintains uniform heat distribution across its entire length, ensuring even toner fusion regardless of paper size or print density. Modern upper fuser rollers incorporate advanced temperature control systems that help maintain precise heating levels, contributing to superior print quality and reduced energy consumption. These rollers are engineered to handle various paper types and weights, from standard office paper to specialty media, while maintaining consistent print quality throughout their operational lifespan.