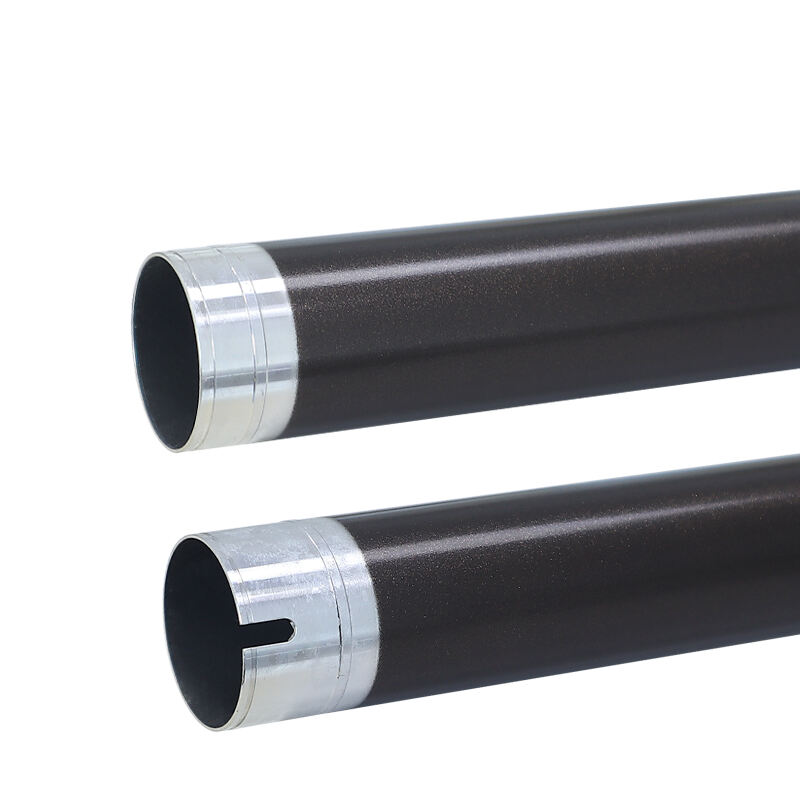

upper fuser roller manufacturers

Upper fuser roller manufacturers play a crucial role in the printing industry by producing essential components for laser printers and copiers. These manufacturers specialize in designing and producing high-quality upper fuser rollers that are fundamental to the printing process. The upper fuser roller works in conjunction with the lower pressure roller to apply heat and pressure to the toner, permanently bonding it to the paper. Leading manufacturers employ advanced materials science and precision engineering to create rollers with optimal thermal conductivity, durability, and uniform heat distribution. These components typically feature specialized coatings, often silicon-based, that prevent toner adhesion while maintaining consistent temperature control. Modern upper fuser roller manufacturing involves sophisticated quality control processes, including automated testing for heat resistance, surface uniformity, and dimensional accuracy. Manufacturers often utilize state-of-the-art production facilities equipped with advanced machinery for coating application, surface finishing, and thermal testing. The production process incorporates strict quality assurance protocols to ensure each roller meets specific performance standards for different printer models and applications. These manufacturers also focus on developing innovative solutions to address common challenges such as wear resistance, temperature stability, and extended service life.