Understanding the Critical Function of Lower Sleeved Rollers in Modern Printing Systems

The printing industry relies heavily on precision components to deliver high-quality results, and among these essential elements, the lower sleeved roller stands as a cornerstone of efficient printing operations. This sophisticated component plays a vital role in ensuring consistent ink transfer, proper paper handling, and overall print quality. As printing technology continues to evolve, understanding the fundamental importance of lower sleeved rollers becomes increasingly crucial for industry professionals and printing equipment operators.

In the complex symphony of printing machinery, every component must work in perfect harmony to produce exceptional results. The lower sleeved roller, positioned strategically within the printing assembly, serves multiple critical functions that directly impact the final printed product. From maintaining proper tension to ensuring even ink distribution, this component's role cannot be understated in the pursuit of printing excellence.

Core Components and Design Features

Essential Structure and Materials

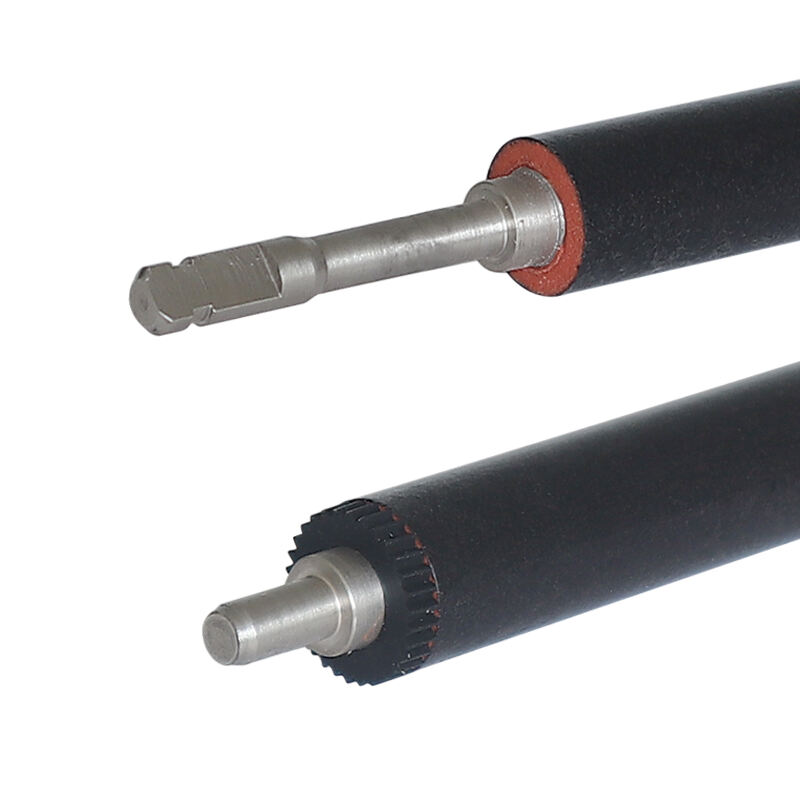

The lower sleeved roller is engineered with precision using high-grade materials that ensure durability and optimal performance. The core structure typically consists of a steel shaft covered with a specially designed sleeve material. This sleeve is carefully selected based on the specific printing application and can be made from various compounds, including chrome-plated steel, synthetic rubber, or advanced polymer composites.

The surface finish of the lower sleeved roller is particularly crucial, as it directly affects ink transfer and paper handling capabilities. Manufacturers employ sophisticated finishing techniques to achieve the perfect balance between grip and smoothness, ensuring consistent performance throughout the printing process.

Advanced Surface Technologies

Modern lower sleeved rollers incorporate cutting-edge surface technologies that enhance their functionality. These may include micro-textured patterns that optimize ink transfer, anti-static treatments to prevent paper adhesion issues, and specialized coatings that extend the roller's operational lifespan. The development of these surface technologies represents a significant advancement in printing roller design, contributing to improved print quality and reduced maintenance requirements.

Operational Functions and Benefits

Ink Distribution Control

One of the primary functions of the lower sleeved roller is to facilitate precise ink distribution across the printing surface. The roller's carefully engineered surface characteristics ensure that ink is transferred uniformly, preventing common issues such as streaking or uneven coverage. This consistent ink distribution is essential for achieving professional-quality prints with sharp detail and uniform color density.

The lower sleeved roller works in conjunction with other printing components to maintain optimal ink film thickness throughout the printing run. This coordination is crucial for preventing issues like ink accumulation or starvation, which can significantly impact print quality.

Paper Transport and Tension Management

Another critical role of the lower sleeved roller involves managing paper transport and tension through the printing system. The roller's surface characteristics and precise engineering ensure that paper moves smoothly through the press while maintaining proper tension. This careful control helps prevent common issues such as wrinkles, misfeeds, or registration problems that can compromise print quality.

Maintenance and Performance Optimization

Regular Inspection and Cleaning

To maintain optimal performance, lower sleeved rollers require regular inspection and cleaning. Accumulated ink, paper dust, and other debris can affect the roller's surface properties and compromise its functionality. Implementing a systematic maintenance schedule helps ensure consistent print quality and extends the roller's service life.

Professional cleaning techniques and approved cleaning agents should be used to maintain the roller's surface integrity. This careful attention to maintenance helps prevent common issues like roller glazing or surface damage that can affect print quality.

Performance Monitoring and Adjustment

Regular monitoring of lower sleeved roller performance is essential for maintaining optimal printing results. This includes checking for signs of wear, ensuring proper roller pressure settings, and verifying alignment within the printing system. Timely adjustments and replacements when necessary help prevent quality issues and minimize production downtime.

Impact on Print Quality and Production Efficiency

Quality Control Factors

The condition and performance of the lower sleeved roller directly influence several key quality control factors in printing. These include color consistency, image sharpness, and overall print uniformity. Understanding these relationships helps operators maintain high-quality standards and troubleshoot issues effectively when they arise.

Regular quality assessments and documentation of roller performance help establish benchmarks for optimal operation and identify when maintenance or replacement is needed. This proactive approach helps maintain consistent print quality and prevent costly production issues.

Production Efficiency Considerations

The proper functioning of lower sleeved rollers significantly impacts overall production efficiency. Well-maintained rollers contribute to reduced waste, faster setup times, and fewer production interruptions. This efficiency translates directly to improved productivity and cost-effectiveness in printing operations.

Future Developments and Innovations

Emerging Technologies

The printing industry continues to evolve, with new technologies emerging that enhance lower sleeved roller performance. These innovations include advanced materials with improved wear resistance, smart monitoring systems that track roller condition in real-time, and surface treatments that optimize ink transfer while reducing maintenance requirements.

Sustainability Considerations

Modern developments in lower sleeved roller technology increasingly focus on sustainability. This includes the use of eco-friendly materials, designs that reduce waste and energy consumption, and solutions that extend roller service life while maintaining optimal performance.

Frequently Asked Questions

How often should lower sleeved rollers be replaced?

The replacement interval for lower sleeved rollers depends on various factors, including printing volume, materials used, and maintenance practices. Typically, rollers should be evaluated every 6-12 months, with replacement necessary when signs of wear or performance degradation become evident.

What are common signs of lower sleeved roller wear?

Key indicators include uneven ink distribution, visible surface damage, inconsistent print quality, and increased difficulty maintaining proper tension. Regular inspection can help identify these signs early before they significantly impact print quality.

Can lower sleeved rollers be refurbished?

Many lower sleeved rollers can be professionally refurbished, which involves resurfacing or replacing the outer sleeve while maintaining the core structure. This can be a cost-effective alternative to complete replacement, provided the base roller remains in good condition.

Table of Contents

- Understanding the Critical Function of Lower Sleeved Rollers in Modern Printing Systems

- Core Components and Design Features

- Operational Functions and Benefits

- Maintenance and Performance Optimization

- Impact on Print Quality and Production Efficiency

- Future Developments and Innovations

- Frequently Asked Questions