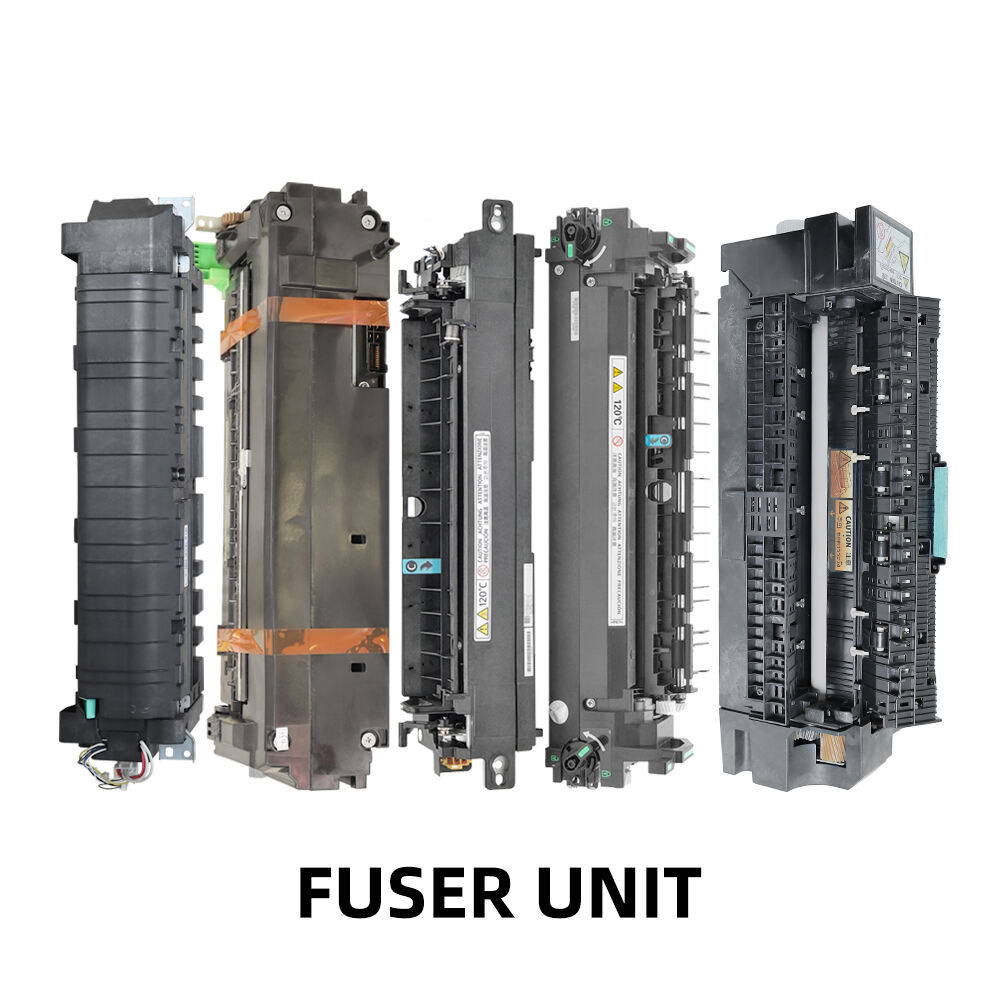

Essential Components of Modern Printer Fuser Units

When it comes to maintaining print quality and ensuring your printer's longevity, the fuser unit plays a pivotal role. This critical component is responsible for permanently bonding toner to paper through heat and pressure. Understanding what makes a quality fuser unit can save you from costly repairs and ensure consistent print quality for years to come.

Whether you're a business owner managing a fleet of printers or an individual looking to replace a worn fuser unit, knowing the key specifications will help you make an informed purchase decision. Let's explore the crucial aspects you need to consider when selecting a new fuser unit for your printing needs.

Temperature Control and Heat Management

Optimal Operating Temperature Range

A high-quality fuser unit must maintain precise temperature control throughout the printing process. The ideal operating temperature typically ranges between 350-425 degrees Fahrenheit, depending on the printer model and paper type. Modern fuser units incorporate advanced thermistors and temperature sensors to ensure consistent heat distribution.

Temperature stability is crucial because fluctuations can lead to various print quality issues. Too much heat can cause paper curling and toner scorching, while insufficient heat results in poor toner adhesion and image flaking. Premium fuser units feature rapid heating elements that reach optimal temperature quickly while maintaining steady heat levels during continuous printing.

Thermal Protection Systems

Advanced fuser units come equipped with sophisticated thermal protection mechanisms. These systems prevent overheating and protect both the printer and printed materials. Look for units with multiple temperature monitoring points and automatic shutdown features that activate when temperatures exceed safe levels.

Heat management efficiency also affects energy consumption and warm-up times. The latest fuser unit models incorporate ceramic heating elements and improved insulation materials that reduce power consumption while maintaining optimal operating temperatures.

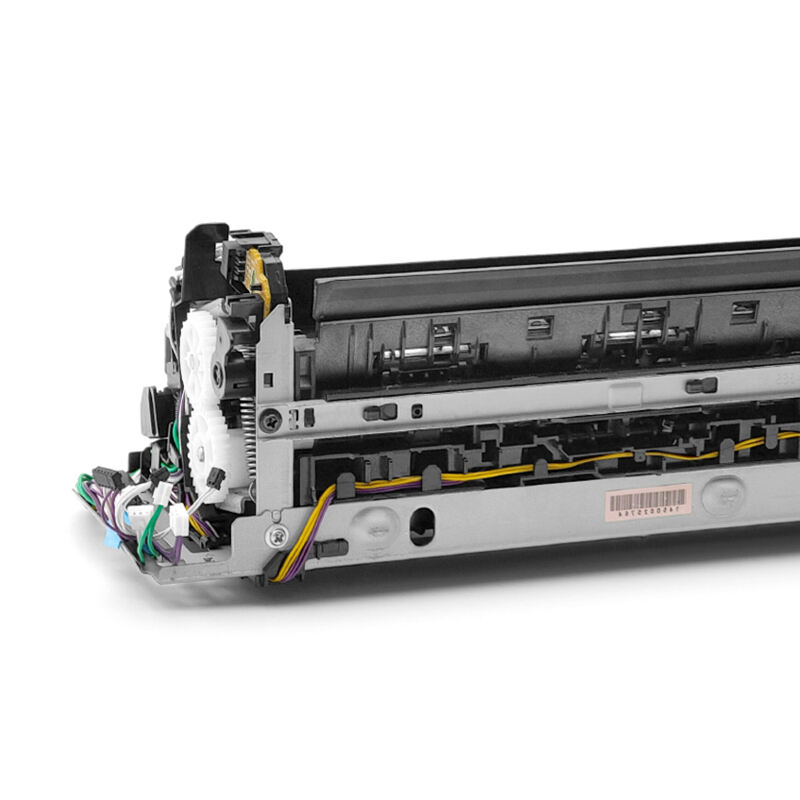

Pressure Roller Specifications

Material Composition and Durability

The pressure roller's material composition significantly impacts print quality and longevity. High-end fuser units utilize silicon-based rubber compounds that offer excellent heat resistance and maintain consistent pressure distribution. The rubber's durometer rating should match your printer's specifications to ensure proper toner adhesion.

Durability is another crucial factor to consider. Premium pressure rollers feature protective coatings that resist wear and prevent paper debris accumulation. These coatings extend the roller's lifespan and maintain consistent print quality over time.

Pressure Distribution Technology

Even pressure distribution across the entire width of the paper is essential for uniform print quality. Modern fuser units incorporate precision-engineered pressure systems that automatically adjust to different paper weights and types. This adaptability ensures consistent toner adhesion regardless of the media being used.

Look for fuser units with self-adjusting pressure mechanisms that can handle various paper weights without manual intervention. This feature is particularly important for offices that frequently switch between different paper types and weights.

Compatibility and Installation Features

Printer Model Verification

Before purchasing a fuser unit, verify its compatibility with your specific printer model. Manufacturers often produce multiple versions of fuser units that may look similar but have subtle differences in specifications. Check both the physical dimensions and electrical requirements to ensure proper fit and function.

Many modern fuser units include smart chips that communicate with the printer's firmware. These chips help monitor performance and ensure compatibility. Always verify that the fuser unit's smart chip is compatible with your printer's software version.

Installation Design and Accessibility

The best fuser units feature user-friendly installation designs that minimize the risk of damage during replacement. Look for units with clear alignment markers, secure locking mechanisms, and protective handles. Some advanced models include tool-less installation features that simplify the replacement process.

Consider the accessibility of connection points and mounting brackets when selecting a fuser unit. Easy access to these components reduces maintenance time and helps prevent installation errors that could damage the printer or the fuser unit itself.

Maintenance Requirements and Lifespan

Service Intervals and Monitoring

Quality fuser units should include clear maintenance schedules and monitoring capabilities. Look for units that provide accurate page count tracking and wear indicators. These features help plan maintenance activities and prevent unexpected failures.

Modern fuser units often incorporate self-diagnostic features that alert users to potential issues before they cause print quality problems. This predictive maintenance capability can significantly reduce printer downtime and maintenance costs.

Expected Lifetime and Warranty Coverage

The expected lifetime of a fuser unit is typically measured in pages printed. Premium units should offer clear specifications regarding their duty cycle and expected lifespan. Consider units that provide comprehensive warranty coverage and manufacturer support.

While initial cost is important, evaluate the total cost of ownership by considering the unit's expected lifetime and replacement costs. Higher-quality fuser units may cost more initially but often prove more economical over time due to their longer service life and reduced maintenance requirements.

Frequently Asked Questions

How do I know when it's time to replace my fuser unit?

Common signs that indicate a fuser unit needs replacement include wrinkled or creased prints, toner that smears easily, repeated paper jams, and unusual noises during printing. Most modern printers also display warning messages when the fuser unit approaches the end of its service life.

Can I clean a fuser unit to extend its life?

While regular cleaning can help maintain print quality, it's important to follow manufacturer guidelines. Use only approved cleaning materials and methods. Some fuser units feature self-cleaning mechanisms, but attempting to clean internal components manually can cause damage and void warranties.

What affects the lifespan of a fuser unit?

Several factors influence fuser unit longevity, including print volume, paper type variety, environmental conditions, and maintenance practices. Using high-quality paper, maintaining proper humidity levels, and following recommended maintenance schedules can help maximize the unit's service life.