Print quality issues like smudging, streaking, and background ghosting can significantly impact business operations and professional document presentation. These defects often stem from inadequate drum cleaning mechanisms within copier and printer systems. Customized cleaning blades represent a critical component in maintaining optimal print quality by ensuring thorough removal of residual toner particles and preventing contamination during the printing process. Understanding how these specialized components function and their role in defect prevention is essential for businesses seeking to maintain consistent, high-quality output from their printing equipment.

Understanding Print Defect Origins and Prevention Mechanisms

Common Print Quality Issues in Office Equipment

Print defects manifest in various forms, each indicating specific mechanical or maintenance issues within the printing system. Streaking occurs when toner particles accumulate on the photoconductor drum surface, creating consistent lines across printed documents. Background ghosting appears as faint images from previous print jobs bleeding through onto current documents, typically resulting from incomplete drum cleaning cycles. Smudging represents perhaps the most noticeable defect, where toner fails to properly fuse or becomes redistributed during the printing process.

These quality issues directly correlate with drum cleaning effectiveness, as residual toner particles interfere with proper image formation and transfer processes. When cleaning mechanisms fail to remove all toner remnants, subsequent print jobs suffer from contamination and poor image clarity. Professional environments cannot afford such quality compromises, as documents reflect directly on business credibility and operational efficiency.

Role of Drum Cleaning in Print Quality Maintenance

The photoconductor drum cleaning process represents a critical stage in the electrophotographic printing cycle, occurring after toner transfer to paper but before the next image formation begins. During this phase, any remaining toner particles must be completely removed to ensure a clean surface for subsequent charge application and laser exposure. Inadequate cleaning leads to toner buildup, charge inconsistencies, and the various print defects previously discussed.

Effective drum cleaning requires precise mechanical contact and appropriate pressure distribution across the entire drum surface. The cleaning blade must maintain consistent contact angle and pressure while accommodating drum rotation variations and wear patterns. This delicate balance between thorough cleaning and drum surface preservation requires specialized blade design and material selection tailored to specific equipment requirements.

Customized Cleaning Blade Design and Functionality

Material Engineering for Optimal Performance

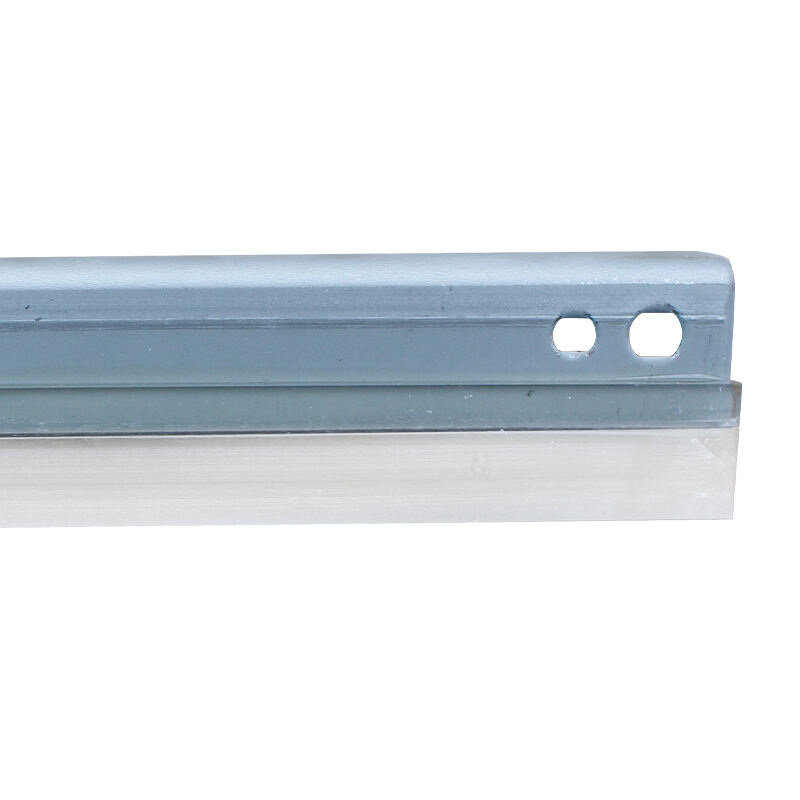

Customized cleaning blades utilize advanced polyurethane compounds specifically formulated for copier and printer applications. These materials exhibit precise durometer ratings that balance flexibility with cleaning effectiveness, ensuring proper conformance to drum surfaces while maintaining sufficient rigidity for toner removal. The molecular structure of these specialized polyurethanes provides excellent wear resistance and maintains consistent performance characteristics throughout extended operational periods.

Surface texture and edge geometry represent critical design elements that distinguish customized cleaning blades from generic alternatives. Precision molding processes create microscopic surface patterns that enhance toner capture while minimizing friction and heat generation. Edge profiles are engineered to specific angles and radii that optimize cleaning contact while preventing premature blade wear or drum surface damage.

Dimensional Precision and Equipment Compatibility

Equipment-specific customization ensures optimal fitment and performance across different copier and printer models. Dimensional tolerances for customized cleaning blades typically maintain precision within hundredths of millimeters, ensuring proper installation and consistent contact pressure distribution. This level of accuracy prevents common installation issues such as blade chattering, uneven wear patterns, or inadequate cleaning coverage that plague generic replacement parts.

Mounting mechanism design varies significantly between equipment manufacturers, requiring specialized knowledge of each system's mechanical requirements. Customized cleaning blades incorporate manufacturer-specific mounting features, spring tension requirements, and positioning mechanisms that ensure seamless integration with existing equipment. This compatibility extends beyond physical dimensions to include operational parameters such as cleaning pressure, contact angle, and thermal expansion characteristics.

Prevention of Specific Print Defects Through Blade Optimization

Eliminating Streaking and Line Artifacts

Streaking defects typically result from localized toner accumulation caused by incomplete cleaning in specific drum surface areas. Customized cleaning blades address this issue through precision edge profiling that ensures uniform contact across the entire drum width. Advanced blade designs incorporate slight curvature or micro-texturing that compensates for drum manufacturing variations and maintains consistent cleaning pressure distribution.

The elimination of line artifacts requires maintaining blade edge integrity throughout operational life cycles. Customized cleaning blades utilize wear-resistant materials and edge treatments that prevent the formation of nicks, chips, or irregular wear patterns that create cleaning gaps. Regular inspection and replacement schedules based on equipment-specific wear characteristics ensure consistent defect prevention throughout blade service life.

Preventing Background Ghosting and Image Contamination

Background ghosting occurs when previous image patterns remain on the drum surface due to inadequate cleaning, creating faint shadows on subsequent prints. Customized cleaning blades prevent this issue through enhanced toner removal efficiency achieved via optimized blade geometry and contact pressure. The blade design ensures complete removal of both loose toner particles and more tenaciously adhered residues that standard cleaning mechanisms might miss.

Image contamination prevention requires addressing both visible toner particles and microscopic residues that can affect charge distribution and image formation. Advanced cleaning blade materials incorporate anti-static properties that prevent toner re-attraction to cleaned drum surfaces. This comprehensive approach to contamination control ensures clean drum surfaces ready for optimal charge application and precise image formation.

Technical Specifications and Performance Characteristics

Durometer Ratings and Material Properties

Shore A durometer ratings for customized cleaning blades typically range from 70 to 90, with specific values determined by equipment requirements and operational conditions. Lower durometer ratings provide enhanced conformability to drum surface irregularities but may wear more rapidly under heavy use conditions. Higher ratings offer extended service life and consistent performance but require precise manufacturing to ensure adequate surface contact and cleaning effectiveness.

Tensile strength and elongation properties directly impact blade performance and longevity. Customized cleaning blades engineered for high-volume applications incorporate materials with enhanced tensile strength ratings exceeding 3000 PSI, ensuring resistance to mechanical stress and operational fatigue. Elongation characteristics typically range from 300 to 500 percent, providing the flexibility necessary for proper drum surface conformance while maintaining structural integrity.

Operational Temperature and Environmental Considerations

Operating temperature ranges significantly affect cleaning blade performance, as materials expand and contract with thermal cycling. Customized cleaning blades utilize materials formulated to maintain consistent properties across typical office equipment operating ranges of 10 to 40 degrees Celsius. Thermal stability ensures consistent cleaning pressure and edge geometry throughout daily operational cycles and seasonal environmental variations.

Humidity and environmental contamination present additional challenges that customized cleaning blades must address through specialized material formulations. Moisture absorption can alter blade dimensions and cleaning characteristics, requiring materials with controlled hygroscopic properties. Anti-static treatments and contamination-resistant surface treatments help maintain cleaning effectiveness in challenging environmental conditions common in office and production environments.

Installation and Maintenance Best Practices

Proper Installation Procedures for Optimal Performance

Correct installation of customized cleaning blades requires attention to specific positioning, tension, and alignment parameters unique to each equipment model. Installation procedures must ensure proper blade contact angle, typically ranging from 20 to 30 degrees relative to the drum surface, depending on manufacturer specifications. Incorrect angles can result in inadequate cleaning, premature blade wear, or drum surface damage that compromises long-term equipment performance.

Mounting tension specifications vary between equipment types and must be carefully observed to prevent blade chattering or excessive pressure that can damage drum surfaces. Customized cleaning blades often include installation guides and tension measurement tools specific to their intended applications. Following manufacturer-recommended procedures ensures optimal cleaning performance while maintaining equipment warranty compliance and operational reliability.

Maintenance Schedules and Performance Monitoring

Regular inspection of cleaning blade condition provides early warning of potential print quality issues before they affect document output. Visual inspection should include examination of blade edge condition, mounting integrity, and evidence of unusual wear patterns that might indicate alignment or pressure issues. Establishing inspection schedules based on equipment usage patterns and environmental conditions helps maintain consistent print quality while optimizing replacement timing.

Performance monitoring through print quality assessment provides objective measures of cleaning blade effectiveness. Regular test printing of diagnostic patterns can reveal developing issues such as incomplete cleaning, blade wear, or contamination buildup before they significantly impact production quality. Documented performance tracking enables predictive maintenance scheduling and helps optimize customized cleaning blade replacement intervals for specific operational conditions.

Cost-Benefit Analysis of Customized Solutions

Economic Impact of Print Quality Issues

Print defects impose significant hidden costs on business operations through wasted materials, reprinting requirements, and reduced document presentation quality. Studies indicate that print quality issues can increase operational costs by 15 to 25 percent when factoring in material waste, labor time for reprinting, and lost productivity from equipment downtime. These costs compound over time, making investment in quality components economically advantageous for high-volume operations.

Professional document presentation directly affects business relationships and credibility, with poor print quality potentially impacting client perceptions and business opportunities. The cost of lost business opportunities due to unprofessional document appearance far exceeds the investment in quality cleaning components. Customized cleaning blades help ensure consistent, professional output that supports business objectives and maintains competitive advantage in document-dependent industries.

Long-term Value and ROI Considerations

While customized cleaning blades typically require higher initial investment compared to generic alternatives, their extended service life and superior performance characteristics provide favorable return on investment over operational lifecycles. Enhanced durability and cleaning effectiveness reduce replacement frequency while maintaining consistent print quality throughout extended service intervals. This reliability translates to reduced maintenance costs and improved operational efficiency.

Equipment protection represents an additional value component of customized cleaning blades, as proper cleaning mechanisms prevent drum damage and extend photoconductor service life. Drum replacement costs significantly exceed cleaning blade expenses, making effective cleaning component selection critical for equipment lifecycle cost management. Customized solutions that properly protect expensive components while maintaining performance deliver substantial long-term value to equipment operators.

FAQ

How often should customized cleaning blades be replaced?

Replacement frequency for customized cleaning blades depends on equipment usage patterns, environmental conditions, and specific blade design characteristics. Typical replacement intervals range from 50,000 to 100,000 print cycles for standard office applications, with high-volume production environments potentially requiring more frequent replacement. Visual inspection of blade condition and monitoring print quality provides the most reliable indicators for replacement timing, as operational conditions vary significantly between installations.

What are the signs that cleaning blades need replacement?

Key indicators for cleaning blade replacement include visible streaking on printed documents, background ghosting or contamination, unusual noise during printing cycles, and visible wear or damage to the blade edge. Progressive deterioration in print quality often provides early warning before complete blade failure occurs. Regular inspection should focus on blade edge condition, mounting stability, and any evidence of toner accumulation around the cleaning mechanism that might indicate inadequate cleaning performance.

Can customized cleaning blades improve the lifespan of other printer components?

Effective cleaning blade performance significantly extends the service life of photoconductor drums, developer units, and transfer mechanisms by preventing toner contamination and abrasive particle accumulation. Proper cleaning reduces mechanical wear on drum surfaces and prevents contamination-related damage to sensitive components throughout the imaging system. This protective effect can extend component life by 25 to 50 percent while maintaining optimal print quality throughout operational cycles.

Are there environmental benefits to using high-quality cleaning blades?

High-quality customized cleaning blades contribute to environmental sustainability through extended service life, reduced component replacement frequency, and decreased waste generation from print defects and reprinting requirements. Effective cleaning mechanisms also optimize toner utilization efficiency and reduce cartridge replacement needs. The combination of longer component life and reduced waste generation supports corporate sustainability objectives while delivering operational cost benefits.

Table of Contents

- Understanding Print Defect Origins and Prevention Mechanisms

- Customized Cleaning Blade Design and Functionality

- Prevention of Specific Print Defects Through Blade Optimization

- Technical Specifications and Performance Characteristics

- Installation and Maintenance Best Practices

- Cost-Benefit Analysis of Customized Solutions

- FAQ