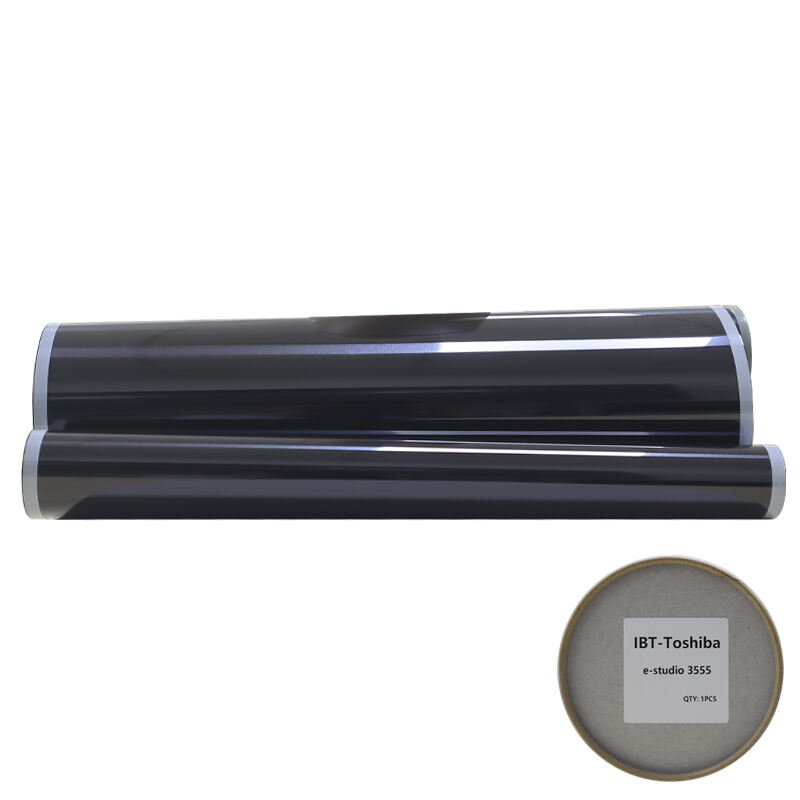

fuser fixing film

The fuser fixing film is a critical component in modern printing technology, serving as an essential element in the heat fusion process that permanently bonds toner to paper. This specialized film consists of multiple layers, including a heat-resistant base layer, a conductive layer, and a release layer that prevents toner from sticking to the surface. During the printing process, the fuser fixing film works in conjunction with pressure rollers to create the perfect combination of heat and pressure needed for optimal print quality. Operating at temperatures ranging from 160 to 200 degrees Celsius, the film ensures uniform heat distribution across the entire printing surface, resulting in consistent toner adhesion and professional-quality output. The film's advanced composition allows for rapid heating and cooling cycles, which contributes to faster printing speeds and reduced energy consumption. Additionally, the fuser fixing film's durability and wear resistance make it capable of handling high-volume printing demands while maintaining consistent performance throughout its operational lifespan. This component plays a crucial role in preventing common printing issues such as ghosting, smudging, and incomplete toner fusion, thereby ensuring that each printed page meets professional standards.