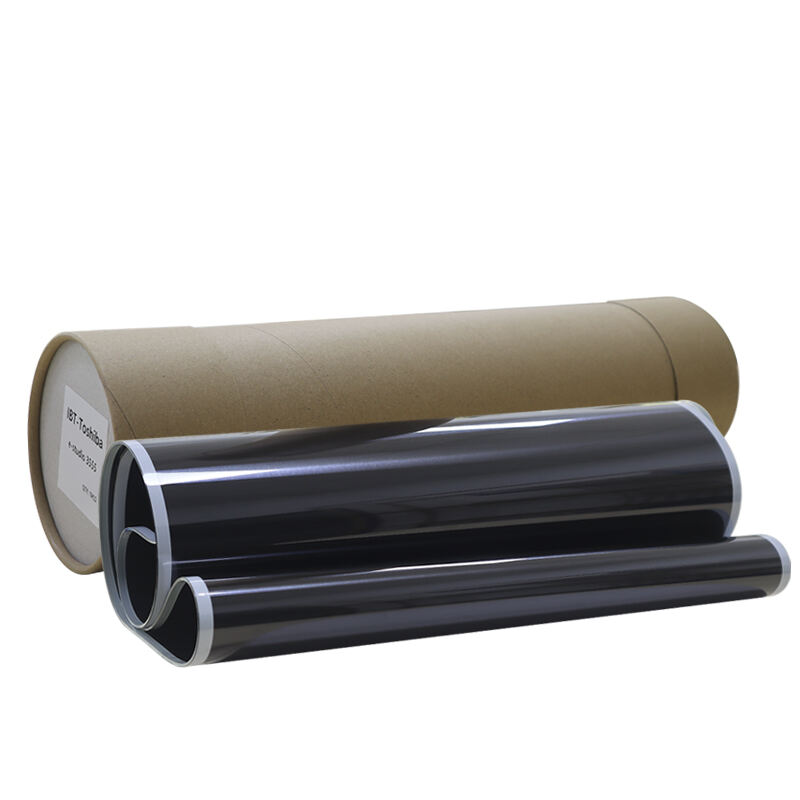

fabrika opc bubnja

Fabrika OPC bubnjeva predstavlja napredno proizvodno objekat posvećen izradi organske fotoconduktorske bubnjeve, ključnih komponenti u savremenim štampačima i kopirnim uređajima. Ovi specijalizovani objekti koriste napredne sisteme automacije i preciznu inženjersku tehniku kako bi stvorili visokokvalitetne OPC bubnjeve koji služe kao srce lazerskih štampača i kopira. Fabrika ugrađuje najnoviju tehnologiju obloge kako bi se primenile fotosensibilne slojeve sa mikroskopskom tačnošću, osiguravajući optimalno kvalitetno reprodukciju slika. Sistemi kontrole kvaliteta koji koriste umetnu inteligenciju i algoritme mašinskog učenja neprestano prate proces proizvodnje, održavajući konstantnu odličnost proizvoda. Objekat poseduje čiste sobe sa kontrolisanim okruženjem kako bi se spriječilo zagađivanje tijekom procesa proizvodnje, jer prašina i čestice mogu značajno uticati na performanse bubnja. Napredna testna oprema procjenjuje električne osobine svakog bubnja, jednolikost obloga i mehaničku otpornost prije odobrenja za distribuciju. Integrisano podjelom istraživanja i razvoja fabrike neprestano rade na unapređivanju procesa proizvodnje i razvoju novih formulacija za poboljšanje performansi i dugovremene funkcionalnosti bubnja. Sa automatiziranom pakovanjskom sistemom i sofisticiranom upravljanjem inventarom, ti objekti mogu održavati velike obimove proizvodnje dok istovremeno osiguravaju kvalitet i pouzdanost proizvoda.