टोनर कार्ट्रिज फैक्ट्री

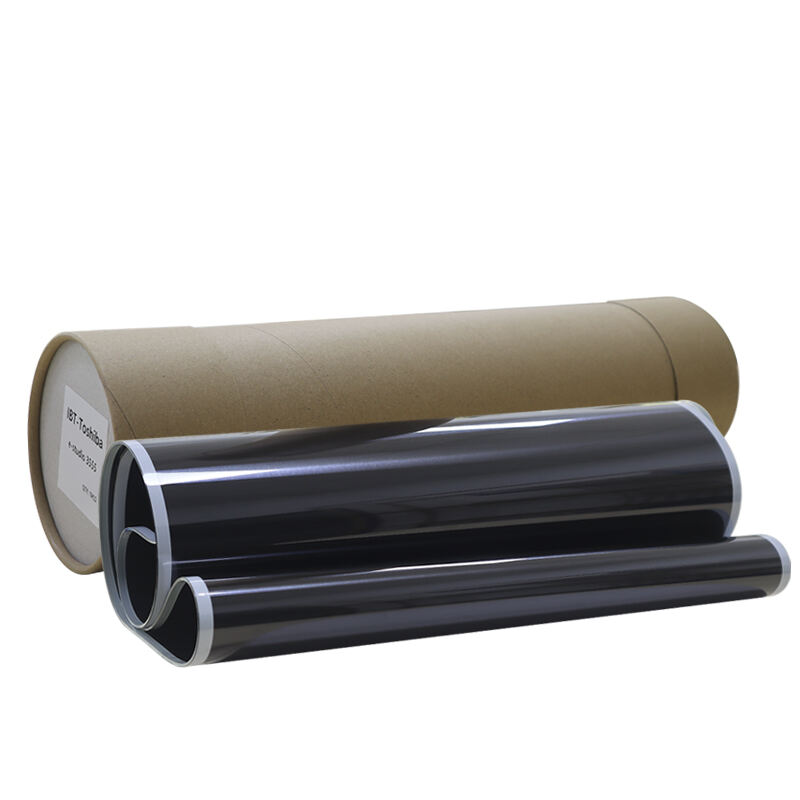

एक टोनर कॉर्ट्रिज फैक्ट्री एक उन्नत विनिर्माण सुविधा का प्रतिनिधित्व करती है, जो लेज़र प्रिंटर और कॉपी मशीनों के लिए महत्वपूर्ण घटकों का निर्माण करने पर केंद्रित होती है। ये अग्रणी सुविधाएँ अग्रणी स्वचालित प्रौद्योगिकी और दक्षता इंजीनियरिंग को मिलाकर उच्च गुणवत्ता के टोनर कॉर्ट्रिज बनाती हैं जो अंतर्राष्ट्रीय मानकों को पूरा करते हैं। विनिर्माण प्रक्रिया में कई विशेषज्ञ उत्पादन लाइनें शामिल हैं, जिन्हें प्लास्टिक मोल्डिंग, टोनर भरने और गुणवत्ता नियंत्रण परीक्षण के लिए अग्रणी मशीनों से तयार किया गया है। प्रत्येक उत्पादन लाइन को विशिष्ट कॉर्ट्रिज मॉडलों के लिए ऑप्टिमाइज़ किया गया है, जिससे समान आउटपुट और कठोर गुणवत्ता पैरामीटरों का पालन किया जा सके। फैक्ट्री में स्वचालित सभी विभागों की प्रणालियाँ, टोनर संधान के लिए स्वच्छ कमरों का पर्यावरण और उन्नत परीक्षण उपकरण शामिल हैं जो उत्पाद की प्रदर्शन क्षमता की जाँच करते हैं। पर्यावरणीय नियंत्रण प्रणालियाँ पूरे सुविधा में आदर्श तापमान और आर्द्रता स्तर बनाए रखती हैं, जबकि उन्नत फ़िल्टरेशन प्रणालियाँ टोनर कण प्रदूषण से बचाती हैं। सुविधा में अनवरत उत्पाद सुधार और नवाचार के लिए अनुसंधान और विकास प्रयोगशालाएँ भी शामिल हैं, साथ ही गुणवत्ता नियंत्रण विभाग जो कठोर परीक्षण प्रोटोकॉल करते हैं। आधुनिक टोनर कॉर्ट्रिज फैक्ट्री स्थिरता को ध्यान में रखती हैं, जिसमें संसाधनों का कुशल उपयोग और पुन: चक्रण कार्यक्रम शामिल हैं, जो पर्यावरणीय जिम्मेदारी के प्रति प्रतिबद्धता दिखाते हैं, जबकि उच्च उत्पादन मानकों को बनाए रखते हैं।