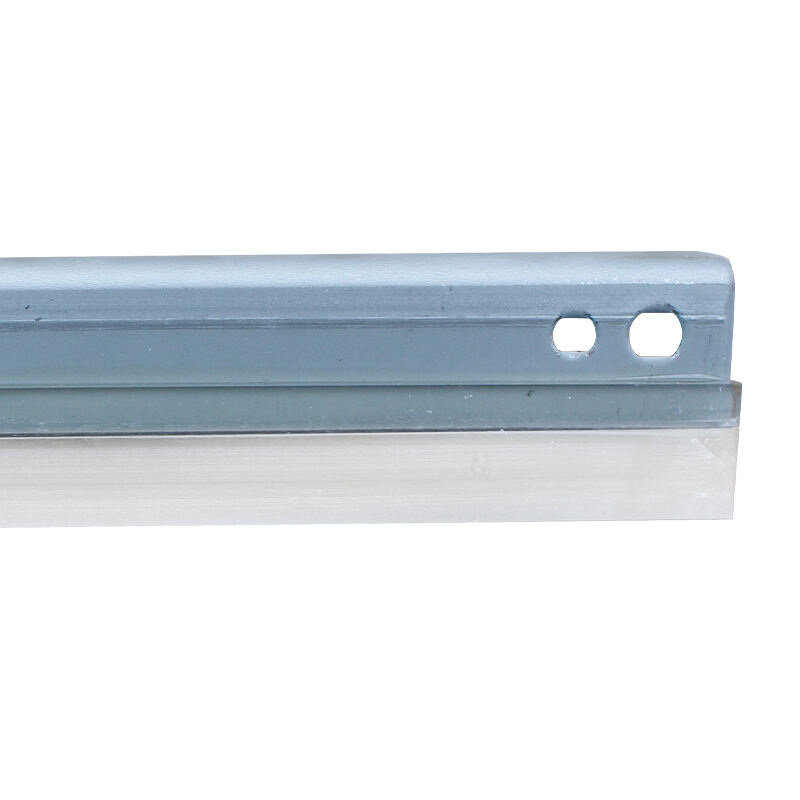

wholesale cleaning blade

A wholesale cleaning blade is an essential industrial cleaning tool designed for efficient surface maintenance and debris removal across various applications. These precision-engineered blades feature high-grade materials, typically including hardened steel or durable polymers, specifically formulated to deliver consistent cleaning performance while minimizing surface damage. The blade's unique design incorporates a precisely calculated angle that optimizes contact pressure and cleaning efficiency, making it particularly effective for removing stubborn residues, dirt, and contaminants from different surfaces. Modern wholesale cleaning blades often include ergonomic handles and adjustable mounting systems, allowing for customizable installation and easy maintenance. These blades are extensively used in printing industries, conveyor systems, manufacturing facilities, and industrial cleaning applications. The design typically features anti-static properties and corrosion-resistant coatings, ensuring longevity and reliable performance in demanding environments. With various sizes and configurations available, these cleaning blades can be adapted to specific cleaning requirements, making them versatile tools for both large-scale industrial operations and specialized cleaning applications.