opc drum manufacturers

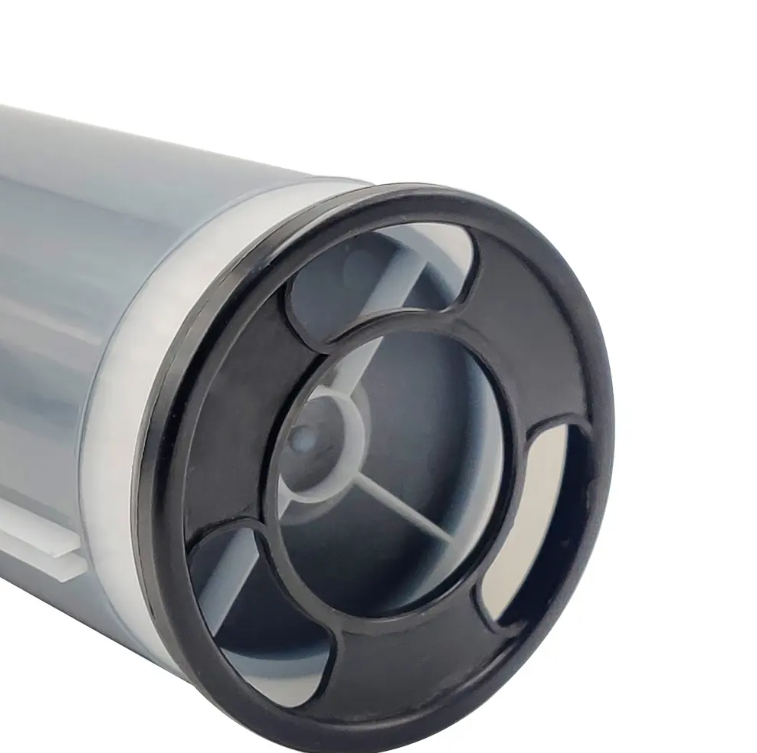

OPC drum manufacturers play a crucial role in the imaging and printing industry by producing one of the most essential components of laser printers and photocopiers. These manufacturers specialize in creating Organic Photoconductor drums, which are light-sensitive cylinders that form the heart of the electrophotographic printing process. Their manufacturing facilities employ advanced coating technologies and precision engineering to produce drums that meet exact specifications for various printing devices. The production process involves applying multiple layers of photosensitive materials onto aluminum cylinders, requiring strict quality control measures and clean room environments. These manufacturers utilize state-of-the-art equipment to ensure consistent quality and longevity of their products. They also invest heavily in research and development to improve drum performance, durability, and print quality. Modern OPC drum manufacturers incorporate automated testing systems and advanced quality assurance protocols to maintain high standards throughout the production cycle. Their products are designed to work seamlessly with various printer brands and models, offering both OEM and aftermarket solutions for the global printing industry.