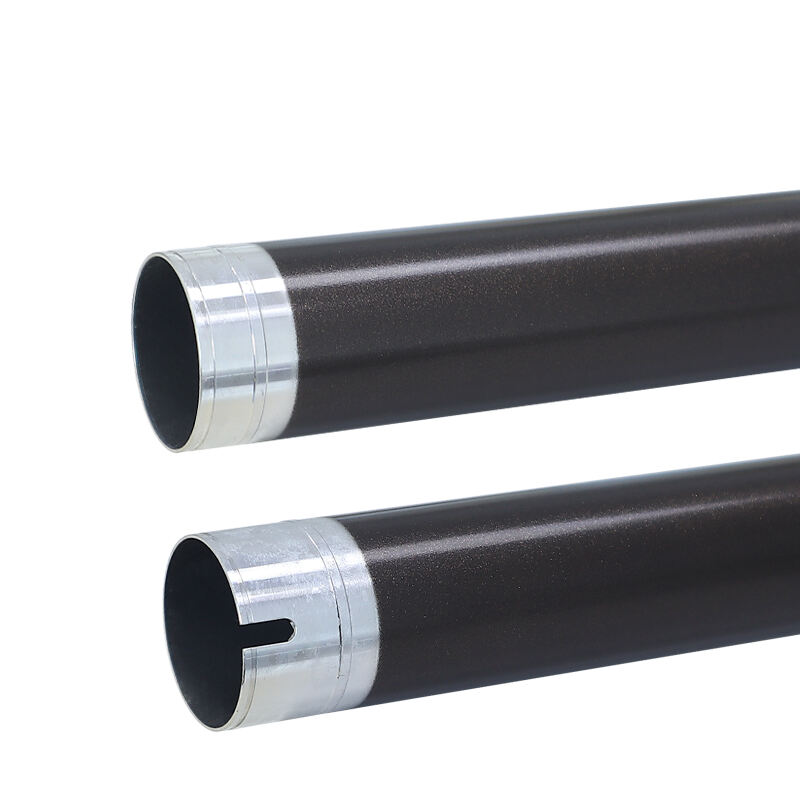

lower sleeved roller suppliers

Lower sleeved roller suppliers are essential partners in industrial manufacturing, providing critical components for conveyor systems and material handling equipment. These specialized manufacturers design and produce high-quality rollers featuring precision-engineered sleeves that ensure smooth operation and extended durability. The rollers incorporate advanced materials and cutting-edge manufacturing techniques to deliver optimal performance in various industrial applications. These suppliers typically offer customization options to meet specific requirements, including different sleeve materials, dimensions, and load-bearing capacities. The rollers feature sealed bearing systems that protect against contamination and reduce maintenance needs. Modern lower sleeved rollers are designed with energy efficiency in mind, incorporating low-friction materials and optimized bearing arrangements. Suppliers often provide comprehensive technical support, including specifications, installation guidelines, and maintenance recommendations. Their products undergo rigorous quality control processes to ensure consistency and reliability. Many suppliers also offer innovative solutions for specific industry challenges, such as high-temperature environments or corrosive conditions. The best suppliers maintain extensive inventory systems and efficient distribution networks to ensure prompt delivery and minimal downtime for their customers.