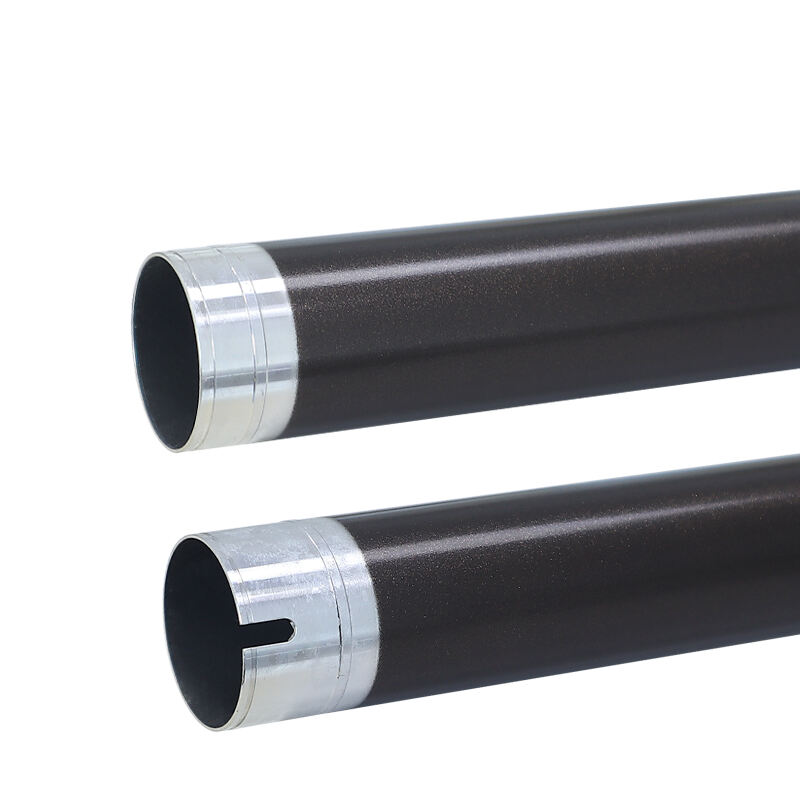

laser printer pickup roller

A laser printer pickup roller is a crucial mechanical component responsible for initiating the paper feeding process in laser printers. This essential part consists of a rubber-coated cylindrical roller designed to grip and feed individual sheets of paper from the input tray into the printer's internal mechanism. The roller's surface features a specialized rubber compound that provides optimal friction and grip while preventing multiple sheet feeding. When the printing process begins, the pickup roller rotates, making contact with the paper stack, and through precise mechanical timing, separates and feeds a single sheet into the printer's paper path. Modern pickup rollers incorporate advanced materials and engineering to ensure consistent paper feeding across various paper types and weights, from standard copy paper to cardstock. The component's design accounts for environmental factors such as humidity and temperature, which can affect paper handling performance. Regular maintenance and cleaning of the pickup roller ensure reliable printer operation and prevent common paper feeding issues such as misfeeds or paper jams. The lifespan of a pickup roller typically ranges from 50,000 to 100,000 pages, depending on usage patterns and paper quality.