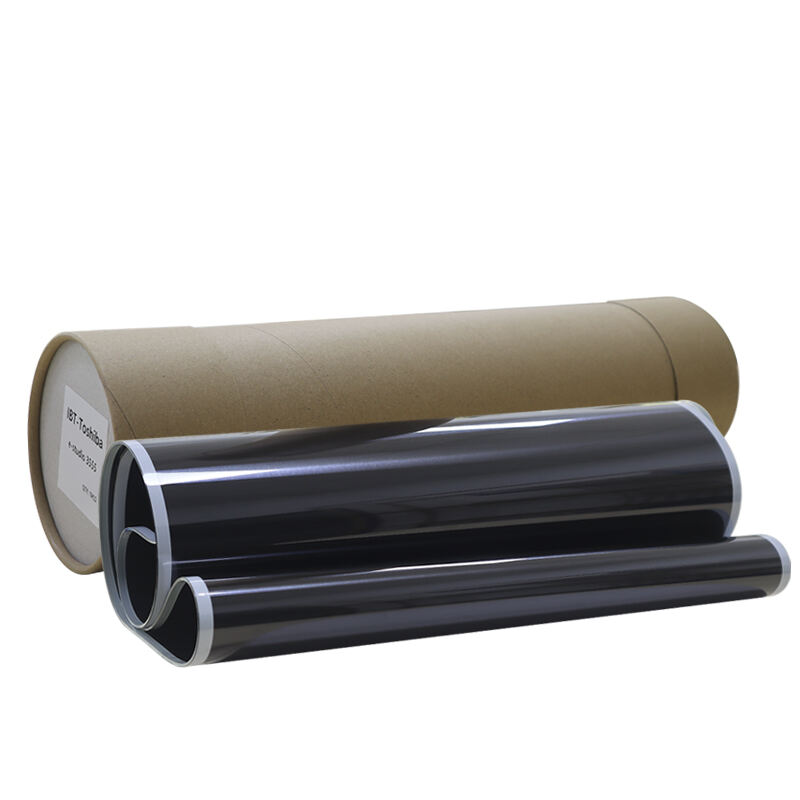

customized transfer belt

The customized transfer belt represents a significant advancement in material handling technology, engineered to meet specific operational requirements across various industries. This versatile solution combines robust construction with adaptable design elements to facilitate efficient movement of materials, products, and components along production lines. Built with premium-grade materials and precision engineering, these belts can be tailored to accommodate different load capacities, speeds, and environmental conditions. The system incorporates advanced tracking mechanisms to ensure consistent alignment during operation, while the customizable width and length specifications allow for seamless integration into existing manufacturing setups. Enhanced surface treatments provide superior grip and product stability, while specialized coatings offer resistance to oils, chemicals, and extreme temperatures. The belt's modular design enables easy maintenance and quick replacement of components, minimizing downtime and operational disruptions. With adjustable tension control and variable speed capabilities, these transfer belts ensure optimal performance across different application scenarios. The system also features advanced safety mechanisms, including emergency stop functions and guard rails, to protect both operators and materials during transfer operations.