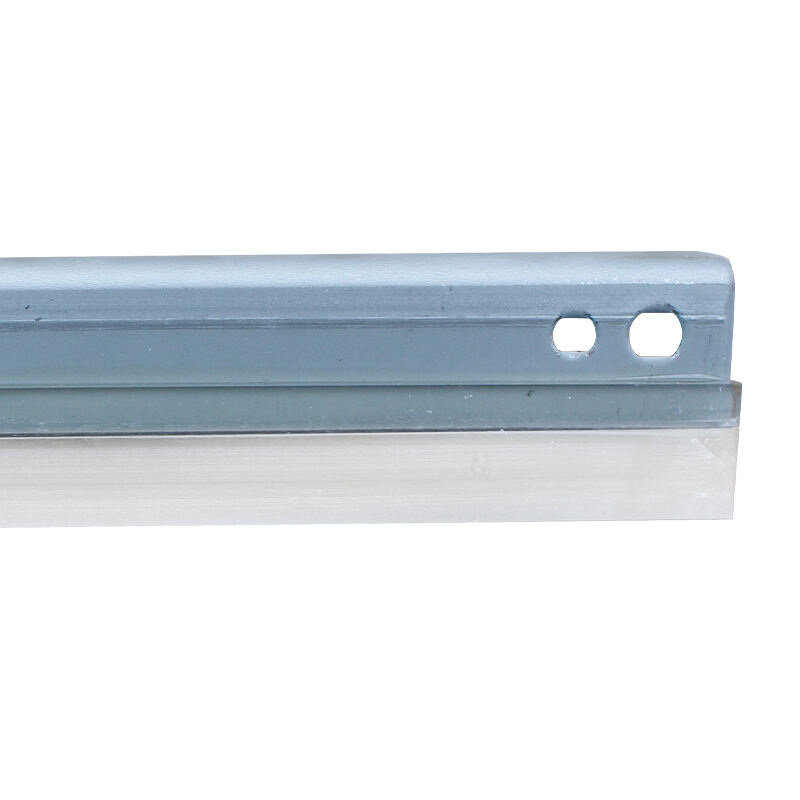

customized drum unit

A customized drum unit represents a critical component in modern printing systems, engineered to meet specific printing requirements and performance standards. This sophisticated imaging component combines precision engineering with advanced photosensitive technology to create high-quality printed outputs. The drum unit functions as the core element responsible for transferring toner onto paper through an electrostatic process. Advanced customization options allow for specifications in drum coating materials, surface treatments, and dimensional parameters to match exact printing needs. The unit's design incorporates specialized photoconductor technology that ensures consistent image quality across various printing conditions. Notable features include enhanced durability through wear-resistant coatings, optimized electrical properties for superior toner transfer, and precision-engineered dimensions for perfect alignment within specific printer models. These units are particularly valuable in professional printing environments where consistent quality and reliability are paramount. The customization extends to compatibility with various toner formulations, printing speeds, and environmental conditions, ensuring optimal performance across different applications.